What is Vacuum Braking System?

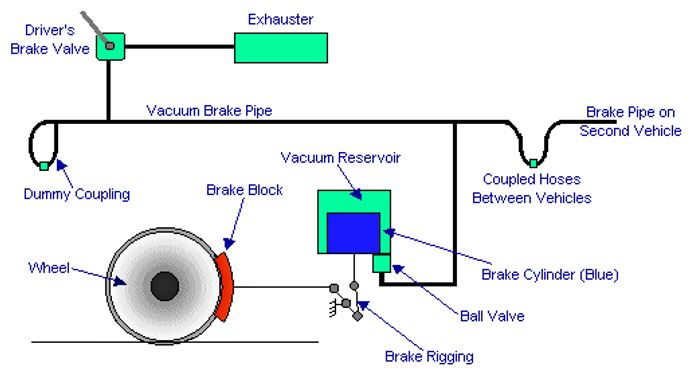

Vacuum Braking System is one of the types of braking system, were mostly used in railway locomotives in the mid 1860’s before the invention of Air Brakes. Railway locomotives were used Vacuum brakes instead of air brakes. Vacuum Brakes mainly consists Brake pipes, Brake Cylinder, and Vacuum Reservoir. The Vacuum pump in Vacuum Brake System creates vacuum in the brake pipe; and the brake cylinder uses the vacuum reservoir for applying the brakes.

Currently, many lite and heavy vehicles are also constructed using vacuum assisted hydraulic braking system (simply, Vacuum Braking System). In this system, the vacuum is created from the engine, which helps the driver’s effort on Foot/Brake pedal. The working of vacuum braking system will be learned in the below sections.

Also Read:

- Hydraulic Braking System – Parts, Working, Types, Advantages, Disadvantages, Application – FAQ’s

- Advantages of Four Stroke Engine over Two Stroke Engine

Parts of Vacuum Braking System:

A Vacuum Braking System mainly consists a two speed rotary machine to evacuate the atmospheric pressure, vacuum carrying pipes and some other important parts of a vacuum braking system are as following.

- Driver’s Brake Valve

- Vacuum Brake Boosters

- Brake Cylinder

- Vacuum Reservoir

- Brake Block

- Brake Rigging

- Exhauster

- Brake Pipe

- Dummy Coupling

Driver’s Brake Valve:

Driver’s brake valve is used to control & monitor the vacuum brakes and brake valve. Their construction series consists a position like Release, Running, Lap, and Brake On and a Neutral or Shut Down position, which is used to lock the valve and the exhauster connects to this brake pipe and switches the exhauster to its full speed to cause rise in vacuum in the brake pipe.

Vacuum Brake Booster:

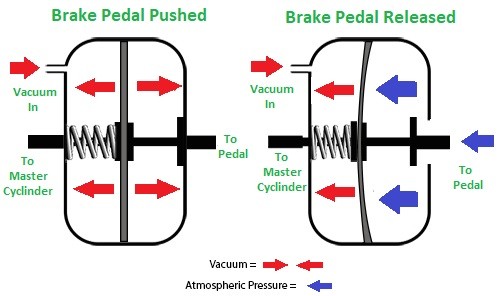

The Vacuum Brake Booster are another important part in Vacuum Braking System. They will boost the performance of the brakes by decreasing the effort of the driver in applying the force on brake pedal. As it is a device, it consists of internal parts that help whole device to work. The internal parts consist Diaphragm, Clever Valve, Metal Canister. The Vacuum Brake Booster is connected to the master cylinder using a rod on one side.

Brake Cylinder:

Every vehicle does consists at least one cylinder but sometimes, there are two or even three cylinders too. The Vacuum Braking pistons inside the cylinders moves to operate the brakes through links called “rigging“. This piston inside the brake cylinder moves with respect to the vacuum in the brake pipe. Loss of vacuum applies the brakes and while restoration of vacuum releases the brakes.

Vacuum Reservoir:

For the operation of vacuum brakes, we need a pressure difference on one side of the brake cylinder piston. Vacuum reservoir in Vacuum Braking System is used to ensure that the source of vacuum is always available for operation, which is attached to the upper part of the piston. In the brake cylinder, the vacuum is integral with the reservoir.

Brake Block:

Brake Block is a friction material in the Vacuum Braking System, pressed against the piston of brake cylinder. This brake block is made up of Cast Iron or some composition material.

Brake Rigging:

Brake Rigging is one more important component or part in Vacuum Brakes in Automobile. The movement of the piston in the brake cylinder transmits pressure to the brake blocks on each wheel by using Brake Rigging System.

Exhauster:

A two-speed rotary machine is used to release the brakes and reduce atmospheric pressure from the brake cylinders and is controlled by the driver’s brake valve. The brake is released at full speed to maintain slow speed of the vehicle. Vacuum will be at their release level when the train is running. The exhauster can be driven directly from the diesel engine.

Brake Pipe:

The pipe carrying the vacuum circulates the pressure difference required to control the brakes over its entire length.

Dummy Coupling:

In Vacuum Braking System, a dummy coupling point is provided on the vehicle on both ends, this allows the ends of the brake pipe hoses to be sealed when the vehicle is uncoupled. Sealed dummy coupling avoids missing from brake pipe.

Working of Vacuum Braking System:

- The Working principle of Vacuum Braking System and air braking system are similar, but in vacuum braking system, the vacuum is used and in air braking system, the compressed air is used to perform the braking operation. In the Vacuum Brakes, a vacuum is created from the engine and used to apply the brakes.

- As we already know that a moving train contains kinetic energy that needs to be removed on the train to stop it. So, the working principle of vacuum system is to convert the kinetic energy into the heat.

- In the Vacuum Braking System, to convert the kinetic energy into heat, we need to add a contact material between the rotating wheels or discs attached to the axles. This material creates friction and converts the kinetic energy into heat that helps to slow the train and stop.

The Working Process of Vacuum Braking System can be explained in two steps

- When we release the brake pedal, the internal vacuum port allows engine vacuum to flow from the check valve of equal vacuum on both sides of the diaphragm’s.

- When we apply brakes, the brake pedal moves forward to close the vacuum port and it allows to open the air inlet valve. The backside of the diaphragm from the vacuum source is blocked by this action and simultaneously, filtered atmospheric air pressure pass through the air inlet valve to the diaphragm backside. This combination of atmospheric pressure on the backside while the vacuum on the front side allows the diagram to move and master cylinder pushrod forward to apply the brakes.

Also Read:

- Braking System – Types, Basic Components, Working, Advantages, Disadvantages, Application – FAQ’s

- Otto Cycle – Process, Graphs, Working, Advantages, Disadvantages, Application – FAQ’s

Advantages of Vacuum Braking System:

The Advantages of Vacuum Braking System are

- It is simple in design.

- The Vacuum Braking System is safety in usage.

- This type of braking system is highly reliable.

Disadvantages of Vacuum Braking System:

The Disadvantages of Vacuum Braking System are

- It is very difficult to find the leakages in Vacuum Braking System.

- The initial cost of Vacuum Braking System is very high.

Application of Vacuum Braking System:

The Application of Vacuum Braking System are

- It is used in Heritage Railway (UK).

- The application of Vacuum Braking System can be found in Narrow Gauge Railway Central Europe.

- It is also used in Railway of India.

- Additionally, the Vacuum Brakes are used in Railway of Spoornet (South Africa) too.

Conclusion:

The working principle of Vacuum Braking System and Air Braking System are similar but the working process and source to apply the brakes are different. The main part that we should remember in this type is Vacuum Brake Booster, which helps the driver to decrease his effort in braking. It is well known and well usage in real applications but still necessary to increase its awareness and technology behind this.

Frequently Asked Questions:

1. What is a Vacuum Brake Booster?

A. The Vacuum Brake Booster will help the drivers to decrease their effort in applying the brakes. In other words, Vacuum Brake Boosters will boost up the performance of the brakes with less effort by Driver.

2. Which car use Vacuum Brake Booster?

A. The Vacuum Brake Booster plays a prominent role in Vacuum Braking so, it will be used in all the cars that use Vacuum Braking System. Specifically, we can say TATA NANO use a 6-inch Vacuum Brake Booster.

3. What is the difference between air brakes and vacuum brakes?

A. In the air braking system, the compressed air is used as the pushing force, which is required to block the wheels. In the air brake system, the brakes are controlled or operated through a brake pipe and it’s also same for the vacuum brake system. But in vacuum brake system, the vacuum is used to apply the brakes.

4. What are the uses of a vacuum brake system?

A. The uses of vacuum brake system are

- More Safety

- Highly Reliable

- Less chances of leakage

5. What is the purpose of Dummy Coupling?

A. Dummy coupling allows the ends of the brake pipe hoses to be sealed when the vehicle is uncoupled.