What is Hydraulic Brake System?

The Hydraulic Brake System is one of the types of braking system in Automobile mainly. The braking mechanism of hydraulic brake system in automobile uses brake fluid mainly Glycol Ethers, or Diethylene Glycol to transmit the force into the mechanical work. The pressure plays major role in transferring the control mechanism to the braking mechanism. Before knowing the working process of hydraulic braking system, we need to know about Pascal’s law because the whole working process of hydraulic brake is the application of Pascal’s law.

The law states that “the pressure applied to any part of a closed liquid is spread equally in all directions” so, when the force on brake pedal is applied, the force is transmitted to the wheel brakes through pressurized fluid, which helps to stop the vehicle.

Parts of Hydraulic Brake system:

Hydraulic Brake system involves many parts and arrangements. the Parts of a Hydraulic Braking System are as follows

- Master Cylinder

- Brake Pedal

- Hydraulic/Brake Fluid Reservoir

- Hydraulic Lines

- Brake Calipers

- Drum Cylinders

Let us read about these parts in detail.

Master Cylinder:

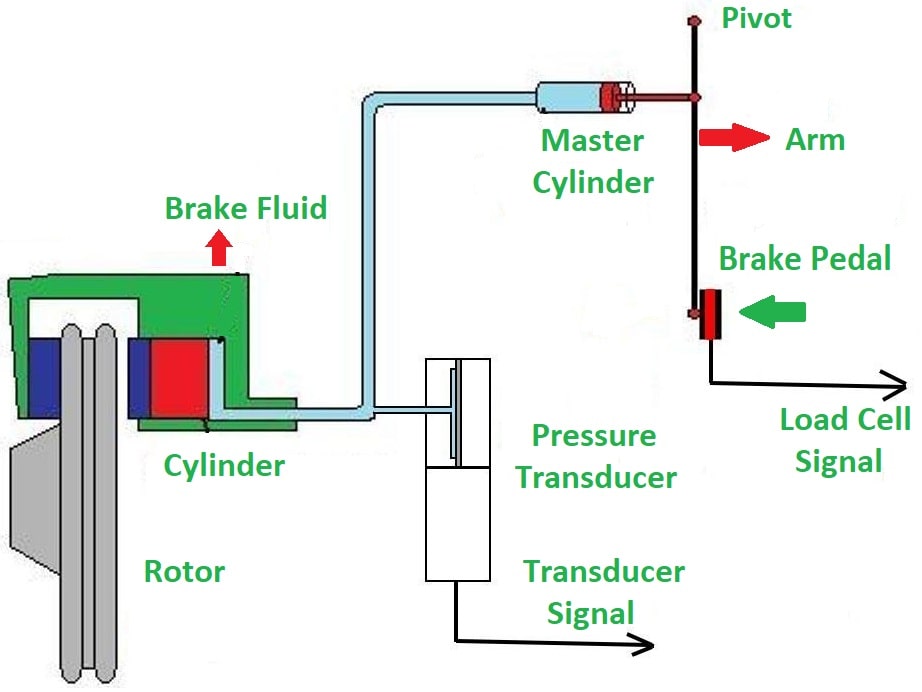

Master Cylinder is the one of the most important parts of the hydraulic braking system. It is a simple cylinder and piston arrangement, which is used to convert foot-pedal force into hydraulic pressure, so it basically acts as a hydraulic actuator.

Within the fluid system (cylinder and piston arrangement), the fluid is compressed and pressurized from the brake pedal to the master cylinder, which is transmitted via hydraulic lines to the brake assembly. The Master Cylinder is connected to the cylinders of all four-wheel via piping; these cylinders and tubes are filled with a fluid that acts as a link to transmit pedal force from the master cylinder to the wheel cylinders.

Brake Pedal:

The brake pedal is used as an input to the master cylinder. The entire assembly of Hydraulic Brake system starts working only when the operator apply pressure on the brake pedal to stop or slow down the running body. It is connected with a small spring that helps the pedal to return. The Master Cylinder is further connected with the brake lever through mechanical rod or connecting rod.

Hydraulic/Brake Fluid Reservoir:

Hydraulic/Brake Fluid Reservoir is a small tank and directly connected to the Master Cylinder for proper operation of hydraulic braking. It is essential to maintain the exact amount of braking fluid throughout the assembly. Sometimes due to small leaks, the fluid level goes down in the master cylinder. To maintain the proper amount of brake fluid in working operation, a reservoir is necessary.

When needed, the braking fluid flows from the reservoir to the master cylinder. It is a simple reservoir tank containing brake fluid, which is connected to the master cylinder with the help of brake hose.

Hydraulic Lines:

Hydraulic lines are the link between the various components of the braking system. Braking fluid passes through these lines from the master cylinder to the brakes. These are small diameter pipes that replace various types of mechanical bonding in the case of mechanical brakes.

Brake Calipers:

Brake Calipers are one of the parts of Hydraulic Braking System, that is attached to the pistons, which helps to stop the vehicle. Brake pads are attached to pistons and calipers on the circumference of the disc. There is a disc in between the calipers.

Drum Cylinder:

A Drum Cylinder is a small cylinder used in drum brakes and is located inside the brake drum, which is attached to both the brake shoes. Drum brakes are internally applied brakes.

Working of Hydraulic Brake System:

The job of Hydraulic Braking System is to perform brakes and is very simple. It consists of two types of components

1. Disc brake.

2. Drum brake.

Only the execution technique differs in both types of brakes. When we apply pressure on the brake pedal, the piston of the master cylinder forces the brake fluid to increase the fluid pressure whereas; this pressure is transmitted to all the pipes and all-wheel cylinders according to Pascal’s law. This increased pressure pushes out the two pistons in the wheel cylinders.

These pistons are connected to the brake shoes so, the brake shoes protrude against the brake drum. The friction between the brake lining and the drum causes the wheels to slow down and even stop the whole vehicle.

1. Disc Brake

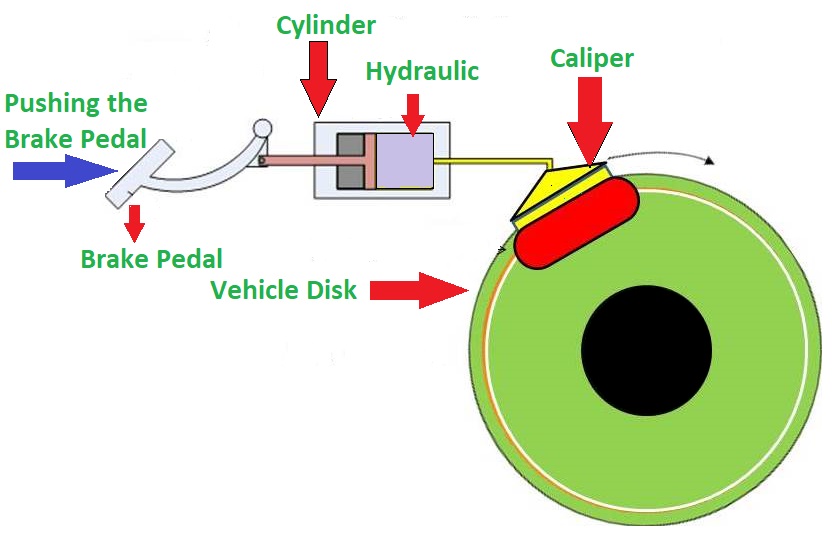

Disc Brake works by applying force on the brake pedal. The action of this compressive force causes the brake fluid to be compressed through a piston-cylinder arrangement into the master cylinder. This compressed fluid creates pressure in the hydraulic supply lines and transfers this pressure energy to the Brake Caliper of the disc brake and the disc is mounted between the calipers.

Both the calipers have piston arrangement and the brake pads are mounted on pistons. As soon as the brake pedal is depressed, the piston starts moving i.e. both the pistons move towards the disc and finally the brake caliper compresses the disc and the brake is executed i.e., the moving parts stop. If we release the brake pedal, the pressure in the hydraulic line drops and the pistons in the calipers move outwards, then the brakes are released.

2. Drum brake

Initially, the working of drum brake and disc brake is similar whereas; the difference lies in the performance of the type of brake. So when the driver applies the brakes in the vehicle, the connecting rod that is connected between the master cylinder’s pedal and the piston will push the master cylinder’s piston inside the master cylinder. This causes compression of the brake fluid inside the master cylinder when this fluid is started. It expands and converts mechanical energy into hydraulic pressure.

Advantages of Hydraulic Brake System:

The advantages of the hydraulic brake system are

- It provides Equal braking action on all wheels.

- It Increases the braking force.

- Hydraulic Brake System is simple in construction.

- Wear rate of brake linings is very low.

- The high flexibility of brake linings.

- Hydraulic Braking System increases the mechanical advantage.

Disadvantages of Hydraulic Brake System:

The disadvantages of the hydraulic brake system are following.

- One of the main disadvantages of Hydraulic Braking System is Leakage. The leakage of fluid from brake linings make whole braking system fail.

- The presence of air inside the tubing is dangerous for whole system.

- The Maintenance of Hydraulic Brake System is high.

- Construction of Hydraulic Brake System is complex.

Applications of Hydraulic Brake System:

The applications of Hydraulic Brake System are

- Hydraulic brakes are mostly used in cars and other automobiles.

- Apart from automobiles, the Hydraulic Brake System can be seen in Oil Field Operations.

- Additionally, it is also used in Wind Turbines.

Conclusion:

The Hydraulic Brake System is being more popular due to its advantages and easy to use. The modern automobiles like bikes, cars, and heavy vehicles are adapting this technology. The fluids used in this system can vary according to its application because the heavy vehicles require more effort or pressure to push the brakes and stop the rotary wheel. Few of its applications can be seen in mopeds nowadays.

Frequently Asked Questions:

What properties of liquid is used in Hydraulic Brake System?

The properties of liquid used in hydraulic brake system are

- It should have high temperature operating capability

- Chemical and physical stability

- Able to resist the corrosion

- Low compressibility

Where are Hydraulic Brakes Used?

Hydraulic Brakes are mostly used in Automobiles like Bikes, Cars, and Heavy Vehicles, etc.

Are Hydraulic Brake System better on Bikes?

Yes, if we observe olden and new model bikes, the performance levels are increased and brakes are very feasible and quick. Such upgrade in performance is due to the adaption of Hydraulic Braking.

What is the difference between pneumatic brake and hydraulic brake system?

The difference between pneumatic brake and hydraulic brake system are

- Pneumatic brakes work on Air whereas; the hydraulic brake works on Fluid (mostly liquid).

- Both systems consist of compressor but the Pneumatic Braking system consists a compressor that is used to compress the air whereas; the hydraulic braking system consists a compressor, which compress the fluid to increase its velocity.

What are the advantages of hydraulic brakes?

The advantages of hydraulic braking system are

- Equal braking action on all wheels.

- Increases the braking force.

- Simple in construction.

- Wear rate of brake linings is very low.

- High flexibility of brake linings.

Are Hydraulic Brakes better than cables?

Yes, the hydraulic brakes are better than cables due to its advantages and performance levels.

How do you add oil to hydraulic brake system?

We can add oil to hydraulic brake system manually, there will be a container or closed vessel that is designed or constructed to store hydraulic oil.

What are Hydraulic Brake Boosters?

The hydraulic brake boosters are type of device that helps to decrease the effort of the users. To stop the vehicle, we have to use much effort to push the brake pedal so, the brake boosters will help us to push the brake pedal gently by doing its work.