What is Lancashire Boiler?

The Lancashire Boiler is a horizontal cylindrical shell shaped, internally fired, low pressure Fire Tube Boiler that consists of Two Fire Tubes (or Multi Tube) for its operation. It was invented by William Fairbairn in the year 1844. The working principle of Lancashire Boiler is similar to a simple Fire Tube Boiler; besides, its construction and working are also similar to the Cornish Boiler, but the difference between Cornish Boiler and Lancashire Boiler is the number of Fire Tubes. The Cornish Boiler consists of only one fire tube, whereas; the Lancashire Fire Tube Boiler consists of two fire tubes.

In-depth, the process of working of all the Fire Tube Boilers is the same. The burnt gases allow to pass through the fire tubes, which helps to convert the water into steam; further, the gases from fire tubes are sent out through Chimney. But, the construction, ability to develop steam rate, firing method, etc., will decide the type of Fire Tube Boiler. So, let us have a look at them.

Also Read:

Boiler – Types of Boilers, Their Parts, Working, Advantages, Disadvantages, Applications – FAQ’s

Water Tube Boiler – Parts, Types, Working, Advantages, Disadvantages, Applications – FAQ’s

What can you learn from this post?

- Parts of Lancashire Boiler

- Construction and Working of Lancashire Boiler

- Advantages of Lancashire Boiler

- Disadvantages of Lancashire Boiler

- Applications of Lancashire Boiler

- Conclusion

- Frequently Asked Questions

Parts of Lancashire Boiler:

The parts of a Lancashire Boiler are similar to the other types of Fire Tube Boilers. The parts that consist by a boiler are called as Mountings and Accessories. The parts or components that are used to perform the operation and its safety are called as Mountings whereas; the devices, parts, or components that are used to enhance the efficiency and steam rate are called as Accessories.

Mountings of Lancashire Boiler:

As known, the Mountings are the parts or components of boilers that are used to perform the operation and assure the safety precautions. The Mountings of a Lancashire Boiler are

- Pressure Gauge

- Grate

- Safety valve

- Water level gauge

- Fire door

- Ash pit

- Blow off valve

- Feed check valve

- Man hole

- Cylindrical shell

- Chimney

- Steam stop valve

- Pressure gauge

Accessories of Lancashire Boiler:

The accessories are the parts or components that enhance the efficiency and output of the boiler. So, the accessories of a Lancashire Boiler are

- Economizer

- Feed pump

- Super heater

- Scoot blower

- Air preheater

- Steam separator

Also Read:

Construction and Working of Lancashire Boiler:

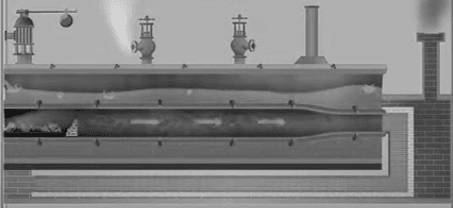

Construction of Lancashire Boiler:

- The Lancashire Fire Tube Boiler is a horizontally constructed, which occupies more floor space and less roof space compared to Cochran Boiler (which is vertically constructed boiler). Besides, it is an internally fired boiler, where the furnace and combustion of fuel will be take place inside the boiler.

- The supply of flue or burnt gases from Furnace into Fire Tube is natural and no artificial devices are used to force the gases. So, it is called as Naturally Circulated Boiler.

- A Furnace is designed at the side ways of Fire Tubes and Damper is used to increase the velocity of burnt gases and guide them directly into the Fire Tubes.

- The Lancashire Fire Tube Boiler consists only two Fire Tubes and not more than that, which develops more steam than Cornish Boiler.

- The Fire Tubes designed with large diameter with short lengths, which then tapered at the ends (at exit of gases) results in increase of velocity.

- The mounting like Steam Stop Valve, and Safety Valve will be placed at top of the boiler.

Working of Lancashire Boiler:

- As like other types of Boilers, the coal or other fuel is combusted in the furnace and allows them to pass into Fire Tube. The increase of water volume will automatically increase the Grate space.

- Due to the presence of Damper, the fuel gases is directly guided into the Fire Tubes.

- The heat of the Gases observed by the water through walls of tubes, which the process is called as Thermal Conduction. Once, the water temperature reaches boiling temperature, the water is converted into steam and then moves upwards of the Boiler, which further into Turbine through Steam Stop Valve.

- The velocity of flue gases increases at the ends and leaves the Fire Tubes into the Chimney.

- The maximum pressure that Lancashire Fire Tube Boiler can develop is 16 bar. Moreover, the maximum steam production rate is 9000 kg/hr.

- Due to its low pressure and steam production rate due to the fire tubes, the efficiency of the Lancashire Boiler lies around 65% to 75 %, which is less than Water Tube Boiler.

Advantages of Lancashire Boiler:

The advantages of Lancashire Boiler are

- The Lancashire Fire Tube Boiler can easily design and construct.

- The operation of this boiler is easy.

- It is more reliable and require less maintenance.

- As it is a low pressure boiler, the Lancashire Boiler is perfect for small and medium industries.

Disadvantages of Lancashire Boiler:

The Disadvantages of Lancashire Boiler are

- As Lancashire Fire Tube Boiler is horizontally constructed, which require large floor space.

- As the fire tubes are surround by large quantity of water, it develops low steam production rate.

- Due to the limited Fire Tubes (two fire tubes), the heat loss chances are more.

- Lancashire Fire Tube Boiler develops Low efficiency, which is around 65 to 75%.

Applications of Lancashire Boiler:

The Applications of Lancashire Boiler are

- It is used in Steam turbines and Marine applications.

- Lancashire Boilers are used in Locomotives Engines to develop the steam for working operation.

Conclusion:

Even though the Lancashire Fire Tube Boiler is a type of Fire Tube Boiler that can generate low pressure and less efficiency compared to Water Tube Boiler, the applications of its kind demands its presence. The increase of fire tubes will result in more steam production rate compared to the Cornish Boiler.

Frequently Asked Questions:

1. What is the difference between Cornish Boiler and Lancashire Boiler?

– The main difference between Cornish Boiler and Lancashire Boiler is number of Fire Tubes. The Cornish Boiler consists of only One Fire Tube, but the Lancashire Fire Tube Boiler consists of Two Fire Tubes.

2. What are the difference between Mountings and Accessories?

Mountings: The Mountings are the devices or parts or components that are used to perform the operations of boiler smoothly and safely. The mountings consist of Pressure Gauge, Steam Check Valve, Stop Valve, Blow Off Valve, etc.

Accessories: The accessories are the devices or parts or components that are used to enhance the efficiency and steam output of the Boiler. The accessories of a boiler include Economizer, Pre Water Heater, Steam Separator, Economizer, Feed pump, Super heater, Scoot blower, Steam Separator, etc.

3. How to increase the Efficiency of a Boiler?

– The Efficiency of a Boiler can be improved by using the accessories in its construction.

4. What is the Maximum Pressure that a Lancashire Boiler can operate?

– As we know that the Lancashire Fire Tube Boiler is a low-pressure operating boiler so, the Maximum Operating Pressure of a Lancashire Boiler does not overgo more than 16 bar.

5. What is the Maximum Efficiency that a Lancashire Fire Tube Boiler can develop?

– The Maximum Efficiency that a Lancashire Fire Tube Boiler can develop is 75% and it may increase by using extra components called Accessories.