What is A Fire Tube Boiler?

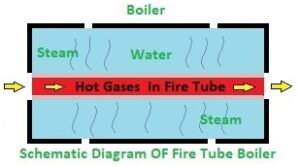

Fire Tube Boiler is a type of Boiler along with Water Tube Boiler, which also called as Smoke Tube Boilers. It consists of single or multi fire tubes in the sealed container (call Boiler) according to produce steam or simply to increase the temperature of water or other sources like Oils, etc. In the Water Tube Boiler, the water flows through tubes and is surrounded by fire or hot gases; just opposite to it, the fire or hot gases are passed through the tubes (call Fire Tubes) and surrounded by water in the Fire Tube Boiler.

Due to the Thermal Conduction, the heat transfers from the walls of tubes to the water, which then water will convert into steam or vapour. Finally, the converted steam is sent to the high pressurized boiler or Turbine to produce the Electricity or to perform required work (check them in Applications below) in Industrial Boilers.

Also Read

- Boiler – Types of Boilers, Simple Working, Advantages, Disadvantages, & Applications – Frequently Asked Questions

- Water Tube Boiler – Types, Their Construction, and Working, Advantages, Disadvantages, And Applications – Frequently Asked Questions

What can you learn from this post?

- Types of Fire Tube Boiler

- Components and Mountings

- Construction and Working of Simple Fire Tube Boiler

- Advantages of Fire Tube Boiler

- Disadvantages of Fire Tube Boiler

- Applications of Fire Tube Boiler

- Conclusion

- Frequently Asked Questions

Types of Fire Tube Boiler:

The Fire Tube is further dividing into many types according to the construction, further for their application area or sector. So, the different types of fire tube boiler are

- Lancashire Boiler

- Locomotive Boiler

- Cornish Boiler

- Simple Vertical Boiler

- Scotch Marine Boiler

- Cochran Boiler

Note: You can read about these types of boilers in detail in upcoming articles.

Components and Mountings:

Feed water valve:

The Feed Water Valve is a type of allowing and restricting passage in the Boiler. It is used to feed or fill the water into the boiler. Additionally, it will stop the water escaping from the closed container or steam container.

Water Level Indicator:

The Steam Developer (call a Boiler) operation is continuous; as water converts into steam, the water quantity decrease so, the operation of the Water Level Indicator is to show and warn the water quantity in the boiler. It will operate to prevent overfilling and feed the water when there is a shortage.

Steam Check Valve:

The Steam Check Valve is helpful to restrict the steam to pass back after being developed in a steam container.

Pressure Gauge:

As we know about the Pressure Gauge, it is used to check the pressure of the water and the steam. According to the pressure gauge results, the boiler operator can maintain the closed container in line.

Manhole:

Manholes are an essential component or passage in the boilers. As boilers are continuous that work at high temperatures, which require maintenance services. It cannot be possible unless we are able to enter into it. So, Manholes are a large passage into the boiler, which enables us to clean it.

Chimney:

The Chimney is an external passage that allows the burnt gases or flue gases to escape from the container or boiler.

Blow Off Valve:

The Blow Off Valve is another component that helps to remove the mud in the water and empty down the water in the boiler. Mostly, the Blow Off Valve is designed at lower bottom sides of a Boiler.

Construction and Working of Simple Fire Tube Boiler:

The Fire Tube Boiler is simple in construction and working. It consists a number of components and mountings as like Water Tube Boiler for its function and maintenance.

The Construction of Fire Tube Boiler is

- As the Boiler is a closed container, the firing will be two types

- Internally Firing Boiler – In this, the furnace or grate is placed inside the closed container, which is below the Tubes and Water. In few constructions, the grate is placed at the entrance of Fire Tubes so, it is easy to allow the flue gases to pass into the Tubes.

- Externally Firing Boiler – In this, the furnace or grate is placed outside the boiler, which is placed below the whole boiler or somewhere around the boiler.

- Mostly, the Fire Tubes are placed horizontally and water is surrounded it. Further, the Fire Tubes may place Vertically, which called as Simple Vertical Fire Tube Boiler.

- The Chimney is always placed at the end of the Fire Tubes or attached to the Boiler Upper Most.

- Mountings and Components like Feed Check Valve, Steam Check Valve, Pressure Gauge, Blow Off Valve, Manholes, etc. will be placed according to the type of boiler and its construction.

The Working of Simple Fire Tube Boiler is

- The Grate is used to develop the fire; the fire may be produced using coal (or solid) or oil. The developed gases are allowed to pass from one of the ends of Fire Tubes.

- The Water is filled or pumped into the boiler, which then checked by Water Feed Check Valve to prevent over feeding and low feeding.

- As the high temperature flue gases are passing in Fire Tube Boiler, the water around the fire tubes will observe the heat through walls of tubes (the process is called as Thermal Conduction).

- Once the water is converted into steam, the steam moves to the top of the Boiler and leaves it through the Steam Valve into Turbine or Supply Pipes.

- Further, the steam is used for producing Electricity or other purposes.

- Besides, the Flue or Burnt gases will leave the Fire Tubes from another side. Further, it is released into the atmosphere through Chimney.

- In this process (converting water into steam), the number of mountings and components used for Boiler operation and to achieve better results, which includes pressure gauge, check valves, manholes, etc.

Advantages of Fire Tube Boiler:

The Advantages of Fire Tube Boiler are

- Fire Tube Boiler is Simple in Construction compared to Water Tube Boiler.

- It is a Low-Pressure Boiler, so it can be used in Small-Medium Industries.

- It requires Low Maintenance Services than Water Tube Boiler so, no worry about cost.

- The Efficiency of the Fire Tube Boiler lies around 75% – 80%.

- It can be operated easily.

- The treatment of Feed Water can be negligible, which saves time and money.

- Due to its simple construction and maintenance, it does not require any high skilled operators.

- The chances of explosion or bursting of boiler will be less compared to Water Tube Boiler.

Disadvantages of Fire Tube Boiler:

The Disadvantages of Fire Tube Boiler are

- Due to the construction and principle of the Fire Tube Boiler, it can be operated at only Low Pressures.

- The Steam developed in Fire Tube Boiler will not be as dry as in the Water Tube Boiler.

- The Fire Tubes are surrounded by water so, the time consuming in conversion of water into steam will be relatively more, which demands more Fire Tubes.

- The efficiency of 80% is less compared to Water Tube Boiler.

- The production rate of steam is low (around 9000 kg/hr).

- Due to its horizontal tube construction, it requires more ground space.

Applications of Fire Tube Boiler:

The Applications of Fire Tube Boiler are

- Due to its low pressure applications, the Fire Tube Boiler is well suitable for Low and Medium Industries that require steam or high temperature water like Textile Industries.

- In few industries, instead of converting the water into steam, the main purpose will be increasing the temperature of water or oil is necessary. So, Fire Tube Boilers are used in such industries

- Furthermore, it can be used in many production companies like Automobile Manufacturing, Food Processing, Pasteurizing of Packaged Foods, etc.

Conclusion:

The Fire Tube Boiler is designed and developed according to the conditions that require for Small and Medium Companies. The increase of Fire Tubes will reflect the output of the steam, which completely depends upon the application. Compared to the Water Tube Boiler, this type of Boiler is safe in operation and easy in construction. Relatively, we can say that the different types of Fire Tube Boilers are evolved according to the requirement of different sectors and their capacity.

Frequently Asked Questions:

1. What are the types of Fire Tube Boilers?

The Type of Fire Tube Boilers are

- Cochran Boiler

- Lancashire Boiler

- Locomotive Boiler

- Cornish Boiler

- Simple Vertical Boiler

- Scotch Marine Boiler

2. Do Fire Tube Boiler is used only for Low-Pressure Application?

Yes, In the Fire Tube Boiler, the fire tubes are surrounded by water, which results in slow and steady conversion of water into low-pressure steam. So, it is not possible for this type of boiler to use at high-Pressure Applications.

3. What is Multi Fire Tube Boiler?

The Fire Tube is a metallic pipe or passage of flue or burnt gases to perform the operation. If the number of tubes in the boiler exceeds 1, then it is called a Multi Fire Tube Boiler. Similarly, if the number of water tubes increases in Water Tube Boiler, then it is called as a Multi Water Tube Boiler. The designing of multi tubes depends upon the output and capacity.

4. What is the Efficiency of Fire Tube Boiler?

The Fire Tube Boiler is a low-pressure boiler and does require much time to convert the water into steam so, the efficiency of the Fire Tube Boiler is less than the Water Tube Boiler. The efficiency of Fire Tube Boiler lies around 75 % to 80 % depends upon the conditions.