What is Cochran Boiler?

The Cochran Boiler is a type of Fire Tube Boiler along with Lancashire, Locomotive, Cornish, Simple Vertical, Scotch Marine boilers. It is an internally fired, vertically constructed, and multi tubular type of boiler that is designed horizontally parallel to the surface. As it is mentioned that the Cochran Fire Tube Boiler is an internally fired type, which means the grate or furnace is constructed inside the closed container and feeding of coal or wood will be done externally.

The working principle of the Cochran Boiler will be similar to the Fire Tube Boiler, where the flue gases will be sent into the Fire Tubes that are surrounded by the water. Then, owing to the high temperature of Flue Gases, the water is slowly converted into steam, which is further sent into turbine for developing the required work.

Also Read

- Boilers – Types of Boilers, Their Construction, Working, Advantages, Disadvantages, And Applications – Frequently Asked Questions

- Water Tube Boiler – Types, Construction, Working, Advantages, Disadvantages, And Applications – Frequently Asked Questions

Table of Contents

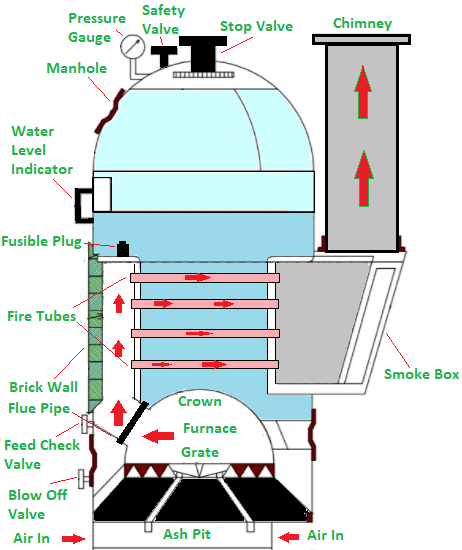

Parts of Cochran Boiler

The parts of boilers can be called as Mountings and accessories. The Mountings are the essential components that ensure the safety of the boiler whereas; the accessories are the extra components that are required to enhance the efficiency of any device (here it is boiler). So, let us read the mountings of the Cochran Boiler

1. Water Level Indicator

The Water Level Indicator is a type of mounting that is used to check the water quantity in the boiler. It will further ensure the feeding quantity. If the water quantity is down surged, then an operator or pump can feed the boiler with water for continuous and smooth operation.

2. Pressure Gauge

The Pressure Gauge is another essential mounting in every boiler, which will indicate or shows the pressure of the steam that developed in the boiler. Therefore, we can say that the pressure gauge is a safety device too.

3. Chimney

The general operation of a Chimney is to send the flue gases from a closed container or closed area into the atmosphere. Therefore, the flue gases that leave the Fire Tubes will be further guided into the atmosphere through Chimney. Generally, it is designed or constructed at the end of the Fire Tubes or one of the sides of the Cochran Boiler.

4. Manhole

The Manhole is a large passage or hole that enables an operator or boiler maintainer to enter and clean the Boiler’s internal components and walls.

5. Safety Valve

The Safety Valve is mounted at the top of the Boiler that will blow off the extra steam that is more than the boiler bearable pressure.

6. Grate

The Grate is a passage that helps the boiler operator to feed the coal or fuel into the boiler. It is usually constructed below the Furnace.

7. Furnace

The Furnace is the space where the wood or coal is combusted to generate fire and gases. The furnace is feed through the Grate which is just above it.

8. Crown

The Crown is the inverted curve structure or hemispherical design over the Furnace. It will create large space in the furnace, which enhances the bearing capacity of the furnace for intense heat generated by combustion.

8. Flue Pipe

The Flue Pipe is the passage of the Flue Gases generated in the furnace into the Fire Tubes. It will not deviate the flue gases entering into other components or holes of the Cochran Boiler.

9. Ash Pit

The Ash Pit is a space under the Furnace, which will collect the ash that remains after combusting the wood or coal. It is the large space that further enables the operators to remove or clean the ash from it.

10. Fusible Plug

The Fusible Plug is a safety device located inside the boiler. It is made up of a particular material that can melt once the temperature of the boiler increases more than the usual temperature, which is harmful and may result in accidents. The melted fusible plug will lay a passage so, the water can enter into the furnace and lit off the fire, and stops combustion.

11. Blow Off Valve

The Blow Off Valve is located at the sides of the boiler that is at lower levels of water. It will help the boiler to remove the mud that water consisted of. Further, it will help to empty down the water in the boiler for maintenance purposes.

Construction and Working of Cochran Boiler

Construction of the Cochran Boiler

- The Cochran Boiler is a vertically constructed one, which means the height of boiler is more than the width. So, it will occupy more roof space than the floor area.

- Even though the boiler is vertically constructed, the Fire Tubes will be designed perpendicular to it (or parallel to the surface).

- The Shell of the whole Boiler and furnace at the top is hemispherical in construction so the boiler can withstand intense heat, which prevents explosions and damage.

- The Furnace is connected to the Fire Tubes at one end so, the burnt gases pass into them and leaves from another end, where the Chimney is connected at another end of the Fire Tubes through Smoke Box.

- The mountings like Safety Valve, Stop Valve, Pressure Gauge, etc. will be attached at the top according to the design.

- The Blow Off Valve will be fixed at the lower ends. Additionally, the Brick Wall will help to resist the escaping of Flue or Burnt Gases.

Working of Cochran Boiler

- As like Simple Fire Tube Boiler, the flue or burnt gases will pass through Fire Tubes from one of the ends and leaves from another end.

- Meanwhile, the heat of burnt gases will absorb by water (surrounded around the Fire Tubes) and convert into steam. Once the Steam developed in the closed container, due to its low density the steam moves upwards and further into the turbine through Steam Valve.

- Due to its design, the minimum working pressure of Cochran Fire Tube Boiler is 6.5 bar, and it can be extended up to a maximum of 15 bar, which depends upon the design and requirement.

- Owing to this, the Cochran Boiler can produce a steam capacity of minimum of 3500 kg/hr and maximum of 4000 kg/hr. The overall efficiency of the Cochran Boiler does not exceed 80%.

- Furthermore, the Pressure Gauge will help the operator to track the pressure developed inside it. The Blow Off Valve will be useful in removing the mud in water and to empty the whole water in boiler.

Advantages of Cochran Boiler:

The advantages of Cochran Boiler are

- It is Used in small and medium industries due to its low pressure applications

- The Cochran Boiler available at Low cost and require less maintenance cost.

- It is easy to operate a Cochran Boiler

- We can use any type of fuel to produce the gases for its operation

- As the Cochran Boiler is Vertical Fire Tube Boiler, it requires low floor area.

Disadvantages of Cochran Boiler:

The disadvantages of Cochran Boiler are

- The rate of steam generation in Cochran Boiler is low.

- As it is a vertically designed Fire Tube Boiler, which require more roof height.

- Due to the slow conversion of water into steam, the Fire Tube Boiler generates only Low pressure steam.

- Due to its design and construction, the maintenance of Cochran Boiler is difficult.

- The Efficiency of the Cochran Boiler is just around 75% to 80%.

Applications of Cochran Boiler:

The applications of Cochran Boiler are

- It is used in Chemical Processing Industries to maintain temperatures.

- Cochran Fire Tube Boiler is used in Refining mills.

- Its functions help a Textile industry for its operations.

Conclusion:

The Cochran Fire Tube Boiler is the best vertical multi tubular boiler that exists. As this is a vertical boiler, it does not require much floor space like other boilers. The steam production rate in Cochran will be increased according to its design; it means the steam production rate is directly proportional to the capacity of the boiler. Additionally, using accessories will increase the efficiency of the boiler, which includes Economizers.

Frequently Asked Questions:

1. What type of boiler is Cochran Boiler?

The Cochran Boiler is a Vertically constructed Multi Tubular internally Fired Fire Tube Boiler.

2. What is the maximum pressure that Cochran Boiler can operate?

The maximum pressure that Cochran Boiler can operate is 15 Bar, which depends upon the boiler design and operation.

3. What is the maximum steam production capacity of Cochran Boiler?

The maximum steam production capacity of Cochran Boiler is 4000 kg/hr, which depends on the installation of a number of Fire Tubes and Combustion.

4. What is the advantage of Crown in Cochran Boiler?

The Crown is the hemispherical structure that is designed for the Cochran Boiler. Owing to this, the space of the boiler increases and further results in the bearing capacity of the boiler for intense heat.