What is Spring Controlled Governor?

Spring Controlled Governor is another type of governor besides Mechanical Governor (or Centrifugal Governor), Gravity Controlled Governor. As the name indicates, this governor works with the help of Spring thus it is names as Spring Controlled. Types of Spring Controlled Governor

- Hartnell Governor

- Wilson-Hartnell Governor

- Pickering Governor

- Hartung Governor

Let us read about these types one by one in more detail.

Table of Contents

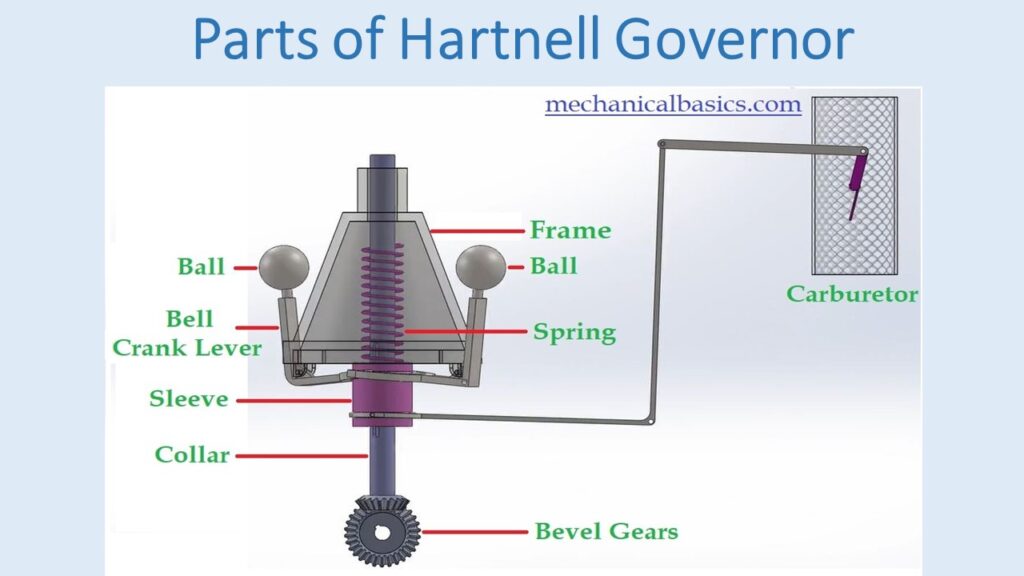

1. Hartnell Governor

What is Hartnell Governor?

The Hartnell Governor is essentially a centrifugal governor with a spring-loaded weight on the sleeve instead of a dead weight to enhance the speed of the balls necessary to lift the sleeve on the spindle. This will allow the governor to activate the mechanism and make the appropriate changes to the fuel supply.

The Hartnell governor works in the same way as all other centrifugal governors, such as the Proell and Porter governors, but instead of a dead load, we have a spring-loaded weight on the sleeve.

Construction of Hartnell Governor

- Hartnell Governors are made up of two bell cranks that are located at various locations on the frame.

- The spindle is coupled to a frame, and each lever transports a ball to the horizontal roller at the end of the vertical arm.

- The helical ring is used to keep the rollers at the same degree of force, while the screw arrangement is used to modify the spring’s force.

Working of Hartnell Governor

- The operation of the Hartnell governor is dependent on the management of the spring force. The spring here spins around the spindle axis, controlling the movement of the ball and sleeves.

- The spring exerts downward force, while the sleeves move upward and downward in response to the pace. Two bell cranks located at the frames carry a ball at one end and a roller at the other.

- As the engine speed increases, the ball rolls outward and the bell crank lever moves at the pivot, raising the sleeves against the spring force.

- These motions are subsequently sent to the throttle valve via machines, resulting in a decrease in fuel supply as well as speed.

2. Wilson-Hartnell Governor

What is Wilson- Hartnell Governor?

The Wilson-Hartnell governor is a centrifugal load governor with a spring-controlled load. In earlier articles, we explored the Hartung governor and the Hartnell governor, both of which are spring-loaded governors with different architectures and functioning principles.

Construction And Working Of Wilson-Hartnell Governor

- The balls are linked to the vertical arm and are coupled to the springs on each side of the sleeves. The spring is made up of two sections, one for each ball.

- The horizontal arm roller makes contact with the sleeves and pushes them, causing the bell-cranks to revolve along the spindle.

- Due to centrifugal force, speed tends to enhance ball movement, and spring is exerted at the inward pressing roller against the sleeves.

- The spring is hooked to the spring on one end and the lever on the other, and it tends to keep the sleeves down.

3. Pickering Governor

What is Pickering Governors?

Pickering Governor is a straightforward speed control governor. A Pickering governor is made of a spindle, nut, spring, weights, and sleeve. The governor’s weights are precise and arranged at equal angles between them. The governor is used to control the speed by rotating the weights linked to the spring.

If the speed is raised, the governor’s sleeve should rise to its maximum height; however, unlike other types of governors such as the proell governor, porter governor, Hartnell governor, and watt governor, the speed of the Pickering governor cannot be increased. Pickering governors are often found in tiny and low-speed engines.

Construction and working of Pickering Governor

- Three springs are positioned around the spindle in Pickering Governor. The arrangement is angular, with each spring holding a comparable weight at its center.

- The spinning balls push on the flat springs, causing the weights to slide outwards. As the ball rotates faster around the axis of the spindle, the spring tries to bend.

4. Hartung Governor

What is Hartung Governor?

There is no need for the load on the sleeve to raise the speed of the balls necessary to lift the sleeve on the spindle in this sort of governor.

Instead, we’ll use the frame to attach the springs directly to the fly balls. Instead of a spring load on the sleeve and a spring load on the fly balls, the Hartung governor works in the same way as the Hartnell governor.

Construction And Working Of Hartung Governor

- This is another form of governor that operates on the basis of the spring movement. The spinning spring balls are attached to the governor bell crank levers in Hartung-type governors.

- These balls are forced up against the governor’s frame, while rollers are pressed up against the sleeves at the horizontal arms.

Advantages of Types of Spring Controlled Governor

Advantages of Hartnell governor

- It has the ability to function at extremely fast speeds.

- Smaller in size

- With very close regulation

- Its pre-compression speed can be modified to get the desired equilibrium speed.

Advantages of Pickering Governor

- Rapid responsiveness to changes in load

- High durability and dependability

Conclusion

Each type of spring controlled governor has its own advantage and disadvantage due to which it is not possible for each type of governor to work in every sector. Even though the working of each type is different, the working principle and the aim of working will be similar. As we know that there are number of types of automobiles vary according to their size, working, power transmission, etc. so, according to that, the governor application is also vary.