What is Electric Braking System?

The Electric Braking System (or Electrical Braking System) is one of the types of braking system, which is also called as Electric Friction Brake or Electric Trailer Brake or Electrical Braking System. Electric Braking System is based on the brake pedal depression strategy and similar to the Drum Braking System but the only difference is that the Electrical Braking System is related to the Electro Magnetic Force while Drum Brakes use Hydraulic Pressure to apply the brakes.

Whenever, the driver pushes the brake pedal, if the braking process take place using Electric Power then it is called as Electric Braking System. The Electrical Braking System is applied in Hydraulic Braking System and Pneumatic Braking System where the mechanical work is done by Hydraulic or Pneumatic and the process is run with Electricity, we use a DC motor to control the Electric brake application and there will be Electronic Control Unit (ECU), which observes the signals from sensors and act according to the situation of the vehicle.

Also Read:

- Braking System in Automobile – Types of Braking in Automobile, Basic Parts, Working, Advantages, Disadvantages, Applications – FAQ’s

- Regenerative Braking System – Parts, Working, Advantages, Disadvantages, Applications – FAQ’s

When our car is in motion it has kinetic energy or in the energy form of motion and in order to slow down the car, this energy must be converted into heat or potential energy. When the load is removed and the supply is cut off from the electric motor but it continues for some time due to inertia and the time before it stops is more if the motor is heavy and running at high speed.

Sudden stoppage of a vehicle is more essential. Delays can cause heavy damage to equipment or manufactured products and may also result in loss of human life.

Types of Electric Braking System

There are three types of Electric Braking System and all of these are applicable to all types of electric motors. They are as follows

- Plugging Braking System (also known as Counter-Current Braking)

- Dynamic Braking System (also known as Rheostat Braking System)

- Regenerative Braking System

Let us have a quick look at these three types of Electric Braking System.

Plugging Braking System

The Plugging Braking System is also called as Counter-Current Braking, which is simplest type of Electric braking system. Generally, when our motor windings are connected to reverse direction of rotation, the armature is rotating in the forward direction under the action of an external torque or due to inertia.

Plugging Braking System reconnect the power supply to the motor so that it can run in the opposite direction. It works as an automatic system. When the brake is released by the driver, the system itself comes to rest and then accelerates in its opposite direction. It is important to mention here that it requires the drive system to rest, and also include a special device that cuts off the supply when the motor stops.

Energy is drawn from the supply during the entire braking process and the energy stored or drawn (kinetic energy) supplied to the rotating parts of the motor and its driving machines is dissipated in the current limiting resistor of the chain.

Dynamic Braking System

The Dynamic Braking System is also called as Rheostat Braking System. In this method, the motor is cut off from the supply and driven as a generator by the rotating parts of the motor, so the kinetic energy is converted into electrical energy, which is dissipated in the external resistance connected to the motor.

By using this method of braking, the energy required from the supply to break the motor is dissipated as compared to the previous method (Plugging Braking System) and is a notable advantage. This method of braking can be applied to braking direct current motors (DC Motors), Synchronous Motors, and Induction Motors (with a separate source of DC excitation during braking).

Regenerative Braking System

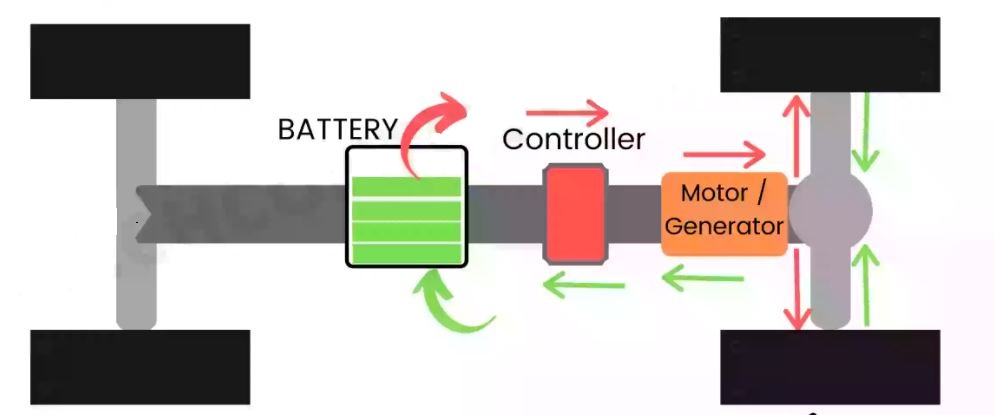

In other methods of Electrical Braking System like Plugging Braking System and Rheostat Braking System do consist rotating parts but in the Regenerative Type of Braking, the energy is utilized that’s being wasted. In Regenerative Braking System, mechanical energy is converted into electrical energy and a part of which is returned to the supply and the remaining energy is lost as heat in the windings and bearings of electrical machines.

Also Read:

- Hydraulic Braking System – Parts, Working, Advantages, Disadvantages, Applications – FAQ’s

- Vacuum Braking System – Parts, Working, Advantages, Disadvantages, Applications – FAQ’s

In general, regeneration involves no switching operation unless there is a need to change the speed at which it becomes effective. Most electrical machines run smoothly from motoring to generating operation when the load is exceeded.

Advantages of Electric Braking System

The advantages of Electric Braking System are

- If we compare Electric Braking with Mechanical Braking then in Mechanical Braking, due to excessive wear on the brake blocks or brake lining, it requires frequent and costly replacement but this type of replacement is not required in Electric Braking System, So the Electric Braking System is cost efficient.

- In Mechanical Braking System, the maintenance is very costly but in electric braking there is no maintenance required.

- Electric braking system can be used for high speeds and heavy loads automobiles like Railways.

- In Electric Braking System, sometimes a part of energy is returned to the supply that makes a considerable saving in the operating cost, which is not possible in mechanical braking.

- Electric brakes are simple in construction.

- Electric brakes operate with electric power so they are faster than other types of brakes.

- Electric braking System are Eco friendly.

- And also, the Electric Braking System does not take much downtime while shutting down and starting again.

Disadvantages of Electric Braking System

The disadvantages of Electric Braking System are

- An additional friction brake is also required with electric braking because motor operates as a generator so it can almost stop a machine or load, but it cannot hold it consistently.

- Applications of Electric Braking System is less due to its limitations.

Applications of Electric Braking System

The applications of Electric Braking System are

- Many Gym Equipment use Electric Braking System to control them.

- It is used in many Industrial Equipment too.

- Recreation Equipment also have Electric Braking System.

- Tesla Model S Use this type of braking system as it works on Electricity or Electrical Energy.

- Rides and Roller Coasters use Electric Brakes.

- High Speed Electric Train also use Electric Brakes.

Conclusion:

As the world is changing its technology from petrol/diesel to electric, it is indeed to follow the electrical technology even with the Braking System. Additionally, an amount of energy developed by petrol/diesel engines are wasted in the name of leaks/loss; to utilize and stopping the losses, the Electrical Braking System will be an advantage. Moreover, the Electrical Brakes are cost efficient and long life compared to other types of braking systems.

Frequently Asked Questions:

Which Energy is absorbed in Braking System?

Ans. The Kinetic Energy is absorbed in the Electrical Braking System whereas; the Kinetic Energy is further converted into Electrical Energy.

Which Brake is cost efficient mechanical or electrical?

Ans. The Electrical Braking System is cost efficient compared to the Mechanical Braking System.

What is the drawback of electrical braking system?

Ans. Special motors are used for generating electrical energy, which is costlier and also the biggest drawback of Electrical Braking System.

What is the difference between Mechanical and Electrical Braking in terms of Heat Produced?

Ans. In Electric Braking System, the heat produced is not harmful to the braking system but the Mechanical Braking heat is produced at brake blocks or brake lining, which results in failure of whole braking system.