What is Regenerative Braking System?

Regenerative Braking System is a type of Electric Braking System, which is also called as Kinetic Energy Recovery Systems. Commonly, all types of braking system in Automobile use friction between two surfaces to slow down moving vehicles by converting the vehicle’s kinetic energy into heat (working principle). But the working principle of Regenerative Braking System (or Energy recovery mechanism) is the process of converting kinetic energy into electrical energy, that can be used immediately or can be stored to apply the brakes.

So, the Regenerative Braking Mechanism (or Energy Recovery Mechanism) is based on converting the kinetic energy created by the mechanical energy of the motor into electrical energy. This type of Braking System can be found mostly in Internal Combustion Engine Cars, Trucks, etc.

Also Read:

- Anti-Lock Braking System – Parts, Types, Working, Advantages, Disadvantages, Applications – FAQ’s

- Vacuum Braking System – Parts, Types, Working, Advantages, Disadvantages, Applications – FAQ’s

Due to the rapid increase in the world population, natural resources conservation has become a requirement in today’s world because the number of vehicles is also rising. Presently, what the world needs is a method or a technology that saves energy from getting wasted, mainly in the modern technology. In driving an automobile involves many braking events, a great amount of kinetic energy is wasted when brakes are applied, which then makes the start-up fairly energy consuming. Due to which higher energy losses take place, energy conservation can be done by using regenerative braking systems (shortly called as RBS).

Table of Contents

Types of Regenerative Braking System

Currently, we have two types of Regenerative Braking System. They are as follow

- Series Regenerative Braking System

- Parallel Regenerative Braking System

Series Regenerative Braking

The Series Regenerative Braking is a type of setup in the Regenerative Braking System, which is combined with a friction-based adjustable braking system. The Series setup transfers energy to the Electric Motors and Battery by using an Integrated Control Mechanism. A series regenerative braking system is complex to implement as compared to the other type of Kinetic Energy Recovery Systems (which is also called as parallel regenerative braking system). But here the energy recovery is higher and the drivability of the vehicle can be preserved.

The Series Regenerative Braking System includes an Auxiliary Power Unit (APU) with an Internal Combustion Engine, which is connected to a generator and rectifier to start the electric motor and recharge the batteries when required. The Electric Motor controlled by the motor control unit that can act as a drive motor or a generator.

Parallel Regenerative Braking System

The Parallel Braking System is an another type of setup in Regenerative Braking System, which is a combination of a friction based braking system without Integrated Controls and a regenerative braking system operated in Tandem. It is also called as Kinetic Energy Recovery System. In simple words, in this setup the friction braking force and the regenerative braking force can’t be adjusted easily. Parallel regenerative braking system do not require a complex control system and it can be used without any alteration to existing friction based braking systems.

However, the energy recovered by the regenerative braking will be less, and may adversely affect vehicle dynamics.

Also Read:

- Hydraulic Braking System – Parts, Types, Working, Advantages, Disadvantages, Applications – FAQ’s

- Braking System in Automobile – Parts, Types, Working, Advantages, Disadvantages, Applications – FAQ’s

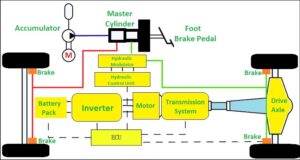

Parts of Regenerative Braking System

As the Regenerative Braking is a type of Electric Braking System; mostly it consists electrical and electronic devices or parts. So, the parts of Regenerative Braking System are

- Electric Traction Motor

- Battery Pack

- Hydraulic Pump

- Accumulator

- Hydraulic Circuit

- Reservoir

- Hydraulic Valves

- Electronic Control Unit (ECU)

We can read about these Regenerative Braking System Components in detail while reading its Working Principle.

Working Principle of Regenerative Braking System

In Regenerative Braking Mechanism (or Energy Recovery Mechanism), when force is applied on the brake pedal, the vehicle slows down and the motor moves in the opposite direction; thus the car engine slows down at an incline. Acting in the opposite direction, the engine acts as a generator and converts torque energy into electrical energy. In this way, there is a reduction in fuel consumption and emissions too.

The Hydraulic Circuit of Regenerated Braking System consists of two circuits; such as drive circuit, and the drain circuit. The drive circuit consists a cartridge valve, which is a one-way valve, and also two-position four-way valve. When the brakes are applied, the valve is shifted to the left and the secondary component using a pump/motor will direct the flow of oil from the reservoir to the accumulator.

And the secondary component operates in pump mode by using the vehicle’s kinetic energy to pressurize the oil into the reservoir to flow into the accumulator. The brake system and control sensors are programed to control all vehicle motors, so that the brake control sensor calculates the power to be generated and the rotating force to the battery by monitoring wheel speed and Torque.

During braking, the brake control sensor controls the electrical energy generated by the motor and directs it to the battery. Moreover, the Ultra-Capacitors and Ultrahigh-Speed Flywheels are also used to store the energy.

Working of Series Regenerative Braking System

During Regenerative Braking Mechanism, the motor works as generator and absorbs current from Auxiliary Power Unit (APU) and Electric Motor. And Hydraulic Valves are used to adjust the frictional braking force, and working valves are installed on the front and rear brake lines that set the air pressure in the brake chambers in different states. When the Electronic Control Unit (ECU) detects a lock on one of the rear wheels, the ABS controller emits a signal which activates the brakes.

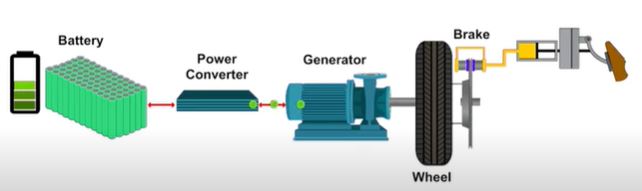

Working of Parallel Regenerative Braking System

During the braking in Parallel Regenerative Braking, the electric motor and mechanical braking system always work together in parallel to slow down the vehicle. Energy Regeneration during braking is important to improve fuel economy and extend its driving range. To increase the use of energy during braking, a negative torque is applied to the wheels of the vehicle to recharge the electric motor battery, which converts some of the kinetic energy into electrical energy.

To keep brake balance during braking, a pressure sensor detects hydraulic pressure indicating deceleration demand in the master cylinder. The pressure signaling is regulated and sent to the electric motor controller to control the electric motor producing the desired brake torque.

In addition, the parallel regenerative braking system (also called as Kinetic Energy Recovery Systems) is simple and inexpensive. With this method, the electric motor can be integrated into the system with a minor modification to the mechanical brake system. Moreover, there is always the advantage of having a back-up mechanical brake system in cases where the brake system fails repeatedly.

Also Read:

- Automatic Transmission System – Parts, Working, Advantages, Disadvantages, and Applications

- Turbocharger and Supercharger – Parts, Working, Advantages, Their Difference Disadvantages, and Applications

Advantages of Regenerative Braking System

The Advantages of Regenerative Braking System are

- It Saves around 30% of energy consumption in Internal Combustion Engine.

- The Regenerative Braking System Increases battery autonomy.

- Regenerative Braking Mechanism is Ideal for frequent stop and go activities.

- The Kinetic Energy Recovery System gives Zero consumption when vehicle stopped but turned on.

- The efficiency is high compared to other types of braking system.

Disadvantages of Regenerative Braking System

The Disadvantages of Regenerative Braking System are

- It Requires additional equipment for control the vehicle, so the cost is high.

- In case of regenerative Braking Mechanism (or Energy Recovery Mechanism), the DC machines of larger size are required, so it increases the weight of the locomotive and thus the required mechanical strength too

- The Kinetic Energy Recovery System makes the operation of substations complex.

- In the case of substations employing mercury-arc rectifiers for the purpose of conversion, additional equipment is required either to deal with the regenerated energy separately or to convert one/more simple rectifiers into reverse operation. No such difficulty is experienced in the case of rotary converters or substations employed for the purpose of converting motor-generator sets.

Applications of Regenerative Braking System

The Applications of Regenerative Braking System are

- Many Electric Vehicles and Hybrid Vehicles use the Regenerative Braking Mechanism such as Hyundai Kona Electric (2019), Audi e-tron (2019), Nissan Leaf (2018), Tesla Model 3 Performance (2019), Chevy Bolts (2017 and 2019) and many upcoming cars.

- Additional to four wheelers (like Cars), even the two wheelers (like bikes) will be equipped with Energy Recovery Mechanism.

Conclusion

The Regenerative Braking System offers several important advantages that friction brake vehicles do not have, for example; if a small deceleration is required (low-speed, stop and go traffic), the Regenerated Braking Mechanism (or Energy Recovery Mechanism) provides the majority of the total braking force with improved fuel economy. In recent years, the increase in use and production of Electric Vehicles for environment safety have led to improvement and advancement in RBS.

Frequently Asked Questions

Which type of Electric Traction Motors are used in Regenerative Brakes?

A. As we know, there are two types of motors AC Motor and DC Motor. In the Regenerative Braking System, both AC and DC Motors can use but to get more efficiency we use Brushless Direct Current (BLDC) motor.

How the Regenerative Braking System saves the fuel?

A. As we spoke in the entire blog, the electric and electronic devices or battery will be charged with unused electricity that’s been developed by the engine so, this is the way that Regenerative Braking saves the fuel.

What is the drawback of Regenerative Braking System?

A. The Drawback of Regenerative Braking are

- The process is more complex and required skilled technicians to operate when it require maintenance.

- As it requires a motor, the space requirement is more and the weight of the whole vehicle will be increased.

What is the working principle of Regenerative Braking Mechanism?

A. The Working Principle of Regenerative Braking Mechanism (also called as Energy Recovery Mechanism) is the conversion of Mechanical Energy into the Electrical Energy by using rotating motor.

Which type of braking is Regenerative Braking System?

A. The Regenerative Braking System is a type of Electric Braking System that uses the electricity, which develops by the mechanical energy of the vehicle