Boiler Mountings And Boiler Accessories

Boilers Mountings and Boiler Accessories are the devices or parts in a boiler that will help in the functioning. They were categorized according to their purpose of usage and application in different types of boilers. Continuing further, it is necessary to learn the types of boilers. Boilers are generally classified into different types according to their working and position of construction, etc. The types of boilers according to few categories are as follows

Also Read

- What is a Fire Tube Boiler – Types of Fire Tube Boilers – Their Working – Advantages – Disadvantages and Applications

- What is Water Tube Boiler – Types of Water Tube Boilers – Their Working – Advantages – Disadvantages and Applications

1. According To The Content In The Tubes

According to the content that is passing through the tubes or pipes, the boilers are divided into two types, namely Fire Tube and Water Tube Boiler.

Fire Tube Boiler – In a fire tube boiler, the fire or hot gas s present inside the tubes and water surrounds these fire tubes. Since fire is inside the tubes, hence it is called as fire tube boiler. Once the hot gases are passing through the tubes, the heat is transferred to the water through the wall.

Water Tube Boiler – In the water tube boiler, the water is present inside the tubes and the fire or hot gases surround these water tubes.

2. According To The Number Of Tubes

According to the number of tubes, the boilers are classified as single tube boilers and multi tubular boilers.

Single Tube Boiler – This type of boiler consist one fire tube or water tube.

Multi-Tubular Boiler – The boiler that has two or more water tubes or fire tubes are called as multi-tubular boiler.

3. According To The Position Of The Furnace

According to the position of the furnace, the steam boilers are classified as internally fire boilers and externally fired boilers.

Internally Fired Boilers – The boilers in which the furnace is located inside the boiler shell are called internally fired boiler.

Externally Fired Boilers – In the externally fired boiler, the furnace is located outside the boiler shell. In this, the furnace is arranged underneath in the brick work settings.

4. According To The Axis Of The Shell

According to the axis of the shell, there are two types of boilers, they are vertical boiler and horizontal boiler.

Vertical Boiler – The boilers in which the axis of the shell is vertical are called vertical boilers.

Horizontal Boiler – When the axis of the shell in a boiler is found horizontal, then it is called as horizontal boiler.

5. According To The Method Of Circulation Of Water And Steam

According to the method of circulation of water and steam, the boilers are of two types, they are natural circulation and forced circulation boilers.

Natural Circulation Boilers – In natural circulation boilers, the circulation of water takes place naturally by the convection currents that setup during the heating of water.

Forced Circulation Boilers – In this type of steam boilers, the water circulation takes place with the help of a centrifugal pump driven by some external power. Here the circulation is forced by some external agencies like motors or pumps.

6. According To The Usage

According to the usage, the boilers are classified as stationary boilers and mobile boilers

Stationary Boilers – These are the boilers that are stationary and cannot be moved from one place to another place. This type of boiler is used in power plants and industrial purposes.

Mobile Boilers – These are the steam boilers that can be moved from once place to another, which can be seen in the steam engine railways.

Also Read

- What is a Cochran Boiler – Its Construction – Working – Advantages – Disadvantages – Applications – And More

- What is Lancashire Boiler – Its Construction – Working – Advantages – Disadvantages – Applications – And More

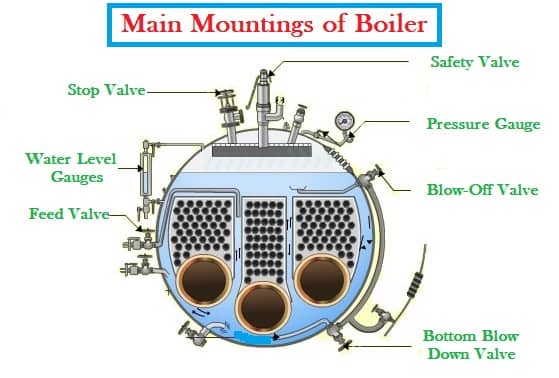

What are Boiler Mountings?

The boiler mountings are fillings, which are mounted on the boiler for its proper functioning. Simply, we can say that the boiler cannot function safely without the mountings. The following are the important boiler mountings.

- Water Level Indicator

- Pressure Gauge

- Safety Valves

- Stop Valve

- Blow Off

- Feed Check Valve

- Fusible Plug

Water Level Indicator

Water Level Indicator is one of the important fittings in the boiler. It indicates the water level in the boiler; once the water is decreased, the water is feed into it.

Pressure Gauge

Usually, the pressure gauge is used to measure the pressure of fluid. In the boiler, the steam pressure is measured.

Safety Valves

The safety valve another type of mounting that is attached to the steam boiler. If the pressure in the boiler increased more than its capacity, then the boiler may explode so, to prevent it the safety valves are used. Once the steam pressure increased more than its capacity, the safety valve will automatically open up and releases the extra steam into the surroundings.

Steam Stop Valve

It is also called as Junction Valve. The function of a stop valve is to control the flow of the steam within the boiler and to stop it completely if required.

Blow-Off Valve

The boiler consist large amount of water, which is feed into it constantly. The water may consists dust, dirt, or any other sediment, which may affect the efficiency and working of the boiler if it proceeds further. So, a blow-off valve is used to remove such sediments that are deposited at the bottom of boiler. Moreover, it is used to empty down the whole boiler if it required any cleaning or overhauling.

Feed Check Valve

When the level of water in the boiler falls, it is brought back of the specified level by supplying the additional water called feed water. The pressure inside the boiler will be high, therefore, the pressure of the feed water has to rise by a pump before it is fed into boiler. The feed water under high pressure is feed into the boiler through the feed check valve.

Fusible Plug

The fusible plug is a tin or leads alloy manufactured device in the mounting. It has a low melting point due to its material type. The function of fusible plug is to put off the fire in the furnace of the boiler where the water falls below an unsafe level and thus avoids the explosion.

What are Boiler Accessories?

Even though the boiler accessories are attached to the boiler itself, there purpose of usage and way of usage is different. The Boiler Accessories are used to improve the efficiency of the boiler or plant. The boiler accessories are as follows

- Economizer

- Air Pre Heater

- Feed Pump

- Super Heater

- Steam Separator

- Steam Trap

Economizer

The combustion gases coming out of the boiler contain a large quantity of heat, which can be used further to increase the efficiency. The economizer is placed in the path of the gases before the chimney (where the gases escape the boiler into the surroundings). They improve the overall boiler efficiency by reducing the fuel consumption.

Air Pre Heater

The air preheater is another type of accessory of the boiler, which recovers the exhaust gas heat by supplying the input air near to it. Supplying preheated air into the furnace produces a high temperature and accelerates the combustion of the fuel, which increases the thermal efficiency of the boiler or plant.

Super Heater

The Super Heater is used in boilers to increase the temperature of the steam above the saturation temperature. The dry saturated steam generated in the boiler is passed through the tubes placed in the path of the flue gases, in which it will be heated further by the hot gas.

Feed Pump

A feed pump in a boiler is required to force the feed water at high pressure into the boiler. Commonly, a reciprocating pump or a rotary pump is used for this type of action or function.

Steam Separator

The steam separator is used to remove water droplets from the steam. Even though the water is converted into the steam, the steam may consist few droplets in it. Usually, the steam separator is installed on the main steam pipe. It is important to remove steam in the water because water droplets in the steam reduce thermal efficiency.

Difference Between Boiler Mountings And Accessories

| Boiler Mountings | Boiler Accessories |

| 1. The components that ensure boiler safety. | 1. Components improve the boiler efficiency. |

| 2. An essential parts of a boiler. | 2. Boiler accessories are not essential if it is for domestic purposes. |

| 3. Mounted on the boiler surface | 3. Integral part of the boilers but not mounted on it |

| 4. Control fluid parameters insides of the boiler shell. | 4. Control fluid parameters outside of the boiler |

| 5. Boiler mounting increases life of boiler but not the efficiency of output. | 5. Boiler accessories do not increase the boiler life, they increase the boiler efficiency. |