What is Reciprocating Pump?

We can observe different types of pumps in our daily life which are work for same purpose even though they are different in their working procedure. In such types, one of them is Reciprocating Pump. It is a type of Positive Displacement Pump, where the pressure is increased using the displacement of the parts or pump. This type of pump converts mechanical energy into hydraulic energy, called pressure energy. Generally a pump is used to lift the water or fluid from lower level to higher level that is possible if we increase the pressure energy of the fluid.

Every energy pump has an impeller (fan), which converts mechanical energy into the pressure energy. But in this reciprocating pump, there will be no impeller, which is also called as Vacuum Pump.

Also Read About: Centrifugal Pump – Its Parts – Working – Advantages – And More

Table of Contents

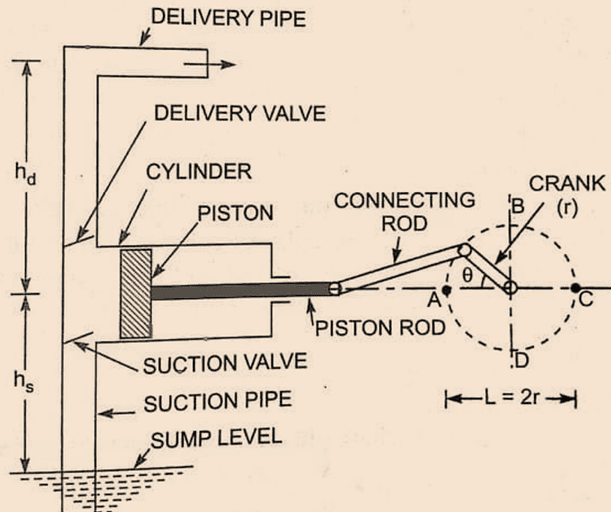

Parts of Reciprocating Pump

Every device consist number of parts, which are responsible for its working and working process. Similarly, the main parts of reciprocating are

- Motor

- Crank wheel

- Crank

- Connecting wheel

- Connecting rod

- Piston

- Piston rod

- Cylinder

- Suction valve

- Suction pipe

- Delivery valve

- Delivery pipe

- Foot valve

Let us read about these parts in detail

Sump

Sump is the main equipment in the whole setup of the centrifugal pump. The water stored in the sump is placed below the pump or at same height.

Connecting Rod

Connecting Rod is a part that connects piston and crank shaft due to which the motion will be transferred from crank shaft to the piston. The rotary motion of the piston is converted to reciprocating motion on the wheel by using connecting rod and crank assembly.

Piston

It is constructed by cast iron and with leather washer cups receiving suction and delivery pressure. It is same like the pistons in the engines. The motion from the crank shaft is transferred to the piston by connecting rod.

The piston movement will create the vacuum, which results in the suction of fluid. Furthermore, the piston will push the fluid and increases the pressure of the fluid to send high heads.

Piston Rod

It is a fixed part that will holds the piston and the connecting rod firmly. The motion of connecting rod and piston is possible only because of their holding power, which is possible by piston rod.

Cylinder

It is a round and enclosed cylindrical part where it consist non-returnable valve. The cylinder consist piston connecting rod, etc. which further responsible for the whole process. The movement of the piston follows the path in the cylinder.

Suction Valve

The suction valve is a non-return valve, which means once directional flow is possible in thin type of valve. This is placed between the suction pipe inlet and the cylinder. During suction of fluid, the valve is opened and during the discharge, it is closed.

Delivery Valve

This is also another type of non-return valve, which is placed between the cylinder and delivery pipe outlet. It is in a closed position during suction and is opened during discharge of liquid.

Suction Pipe

It is used to suck the water from the water reservoir or sump into the cylinder. It connects the inlet of the pump with the water tank.

Types of Reciprocating Pumps

There are three types of Reciprocating Pumps according to the mechanism, air vessel, and number of function cylinders. They are

1. According to Type of Mechanism

- Single-acting Reciprocating Pump

- Double-acting Reciprocating Pump

2. According to Type of Air Vessel

- Pump with Air Vessel

- Pump without Air Vessel

3. According to Number of Cylinders Functioning

- Single Cylinder Reciprocating Pump

- Double cylinder Reciprocating Pump

- Triple cylinder pump

Note – We will read about these types of reciprocating pumps in detail in the upcoming posts.

Also Read About – Difference Between Reciprocating Pump and Reciprocating Compressor

Working Principle and Working of Reciprocating Pump

As said, the working principle of reciprocating pump is to convert the mechanical energy into pressure energy such a way that the fluid can able to acquire energy to flow from lower heads to the higher heads. The working principle can be achieved using the vacuum that is created in the space of the upper section of the piston due to which the pressure forces the water up through the suction pipe into the cylinder.

- The main parts that can be notable while working are piston and cylinder. Pressure energy is created in the space of cylinder.

- The piston or a plunger reciprocating inside a close fitted cylinder whereas; each pipe provided with a non-return valve to ensure that fluid cannot flow backward direction.

- Liquid enters on one side of piston due to vacuum created by its reciprocating action inside the cylinder followed by crank rotation. The to and fro motion of the piston achieve using the Motor, which further creates suction and compression inside the cylinder.

- This pump mainly depends on two strokes of piston namely suction stroke and discharge stroke.

- Suction stroke

The suction stroke is when the crank turns in clockwise direction. The piston moves from left to right creating vacuum in pressure below the atmospheric level in the left space of the cylinder. This vacuum causes suction of the liquid from the sump, opening the inlet valve. The suction stroke is completed, when the crank reaches position.

- Discharge stroke

Discharge stroke is when the crank further turns the position moves towards left, increasing the pressure inside the cylinder. The high pressure inside the cylinder causes the suction valve to close and delivery valve to open. Therefore, the high pressure liquid flows out of the cylinder into the delivery pipe; the discharge stroke will be completed when the crank reaches the position.

- The suction and delivery stroke are alternatively carried out and pulsating output is obtained. Due to this, two strokes or processed, the fluid acquire pressure energy and which makes them capable enough to move from low level to the upper level through the pipes.

Advantages of Reciprocating Pump

The advantages of Reciprocating Pump are

- Reciprocating Pump is suitable for low discharge and high head.

- It does not require any priming.

- It has high efficiency.

- Reciprocating Pump provides steady and unchanging flow rate.

Disadvantages of Reciprocating Pump

The disadvantages of Reciprocating Pump are

- It is intermittent in operation and hence it delivery fluctuations.

- Reciprocating Pump is a low speed machine. So speed is limited due to the cavitation.

- Pump maintenance is difficult and high cost.

- The flow rate is low and not suitable for high operations.

- Reciprocating Pump has no uniform torque.

- Not suitable or it is not able to pump the viscous liquids easily.

Applications of Reciprocating Pump

The applications of Reciprocating Pump are

- This type of pumps are generally use in service stations.

- Reciprocating pumps can be found in Oil and Gas industries and in petroleum industries too.

- They can be seen in production companies like Food, Sugar, etc.

- They play key role in increasing the pressure of fluid in Workshops for cleaning the parts.

Frequently Asked Questions

1. What is difference between reciprocating and other pumps?

In reciprocating pump is delivery of fluid in fluctuating. Other pump is flowing in uniform pressure.

2. Which is more efficient pump reciprocating or centrifugal pump?

When comparing reciprocating pump with centrifugal pump; the centrifugal pump is more and high efficient at low heads.

3. Difference between reciprocating pump and centrifugal pump

The main differences between reciprocating pump and centrifugal pump are

- Flow of Fluid

- Type of Working

- Efficiency and

- Pressure

4. Why is reciprocating pump called as positive displacement pump?

The Reciprocating Pump is called as the Positive Displacement Pump because the pressure of the liquid in the reciprocating pump is increased due to the pushing or displacement of the piston.

5. What is Priming?

In the pump, sometimes the suction line may flows back and these spaces will be filled with air when it is idle. So the filling of liquid to remove the air from the pump suction line or pipe is called as Priming. A reciprocating pump has this type of problem or process.