What Is A Water Tube Boiler?

Water Tube Boiler is one of the types of Boiler where the water is feed (called feed water) and circulated in metallic tubes called Water Tubes. To heat the water and generate steam, the water tubes are surrounded by fire.

So, the heat of the fire is transferred to the water in the tubes and increases the temperature; whenever the temperature of the water reaches a certain level, the water converts into steam and sent to the Turbine. Such arrangement and process of converting the water into the steam in the water tubes are called a Water Tube Boiler. The Water Tube Boilers can be used up to a pressure level of 250 Bars.

The working principle of the water tube boiler can be simply stated as “conversion of feed water in the tubes into steam using the fire around the water tubes.”

Also Read:

- Boilers – Types Of Boilers, Boiler Operation, Advantages, And Applications

- Cast Iron – Properties, Types, Advantages, Disadvantages, And Applications

Types Of Water Tube Boilers:

The operation and working principle of all types of water tube boilers are similar but further there are three different types of boilers that are classified according to the water tube boiler construction, Firing type, and Alignment. They are as follows

- Horizontal Straight Water Tube Boiler

- Cyclone Fired Water Tube Boiler

- Bent Tube Boiler

1. Horizontal Straight Boiler

The Horizontal Straight Boiler is classified according to the water tube boiler construction where the Water Drum will be placed horizontally and the water tubes will be either parallel to the water drum or inclined at some angle.

The horizontal straight boiler is further classified into two types according to the alignment of the water storage or drum. They are

- Longitudinal Drum Boiler

- Cross Drum Boiler

2. Cyclone Fired Boiler

The Cyclone Fired Boiler is one of the Water Tube Boiler Types that is classified according to its firing and combustion. It is mainly named for its process of firing and combustion.

Firstly, the crushed coal is feed into the burner with some air called primary air. As soon as the burner starts producing fire, the forced air called secondary air is send into the burner so, the air will flow tangentially to achieve great firing and fast combustion which we call as Cyclone Firing.

3. Bent Tube Boiler:

Bent Tube Boiler is one of the classifications of Water Tube Boilers. As the name indicates, the Water Tubes in the Boiler is bent in different ways so, the feeding water can circulate and convert into steam.

There are four types of Bent Tube Boilers according to the number of tubes in water tube boiler construction. They are

- Two Drum Bent Tube Boiler

- Three Drum Bent Tube Boiler

- Low Head Three Drum Bent Tube Boiler

- Four Drum Bent Tube Boiler

Water Tube Boilers Examples:

According to the classifications and water tube boiler types; in earlier days, many companies and designers had invented different water tube boilers and named them. We can convey them as Water Tube Boiler Examples and a few of them that are popular in usage are as follows

- Simple Vertical Boiler

- Babcock And Wilcox Boiler

- Stirling Boiler

- Yarrow Boiler

- Loeffler

- Lamont Boiler

- Benson Boiler

1. Simple Vertical Boiler:

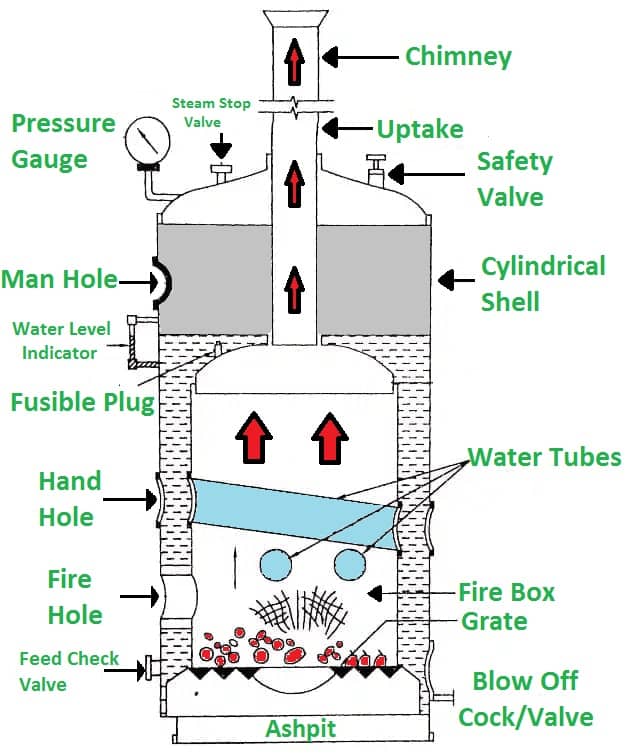

The Simple Vertical Boiler is an example of a Vertical Type Boiler where the Water Drum is constructed vertically and the water tubes are perpendicular to the water drum (with some inclination). The firing is introduced from the bottom of the water tube. A few components and devices used in the Simple Vertical Boiler Construction are as follows

- Cylindrical Shell

The Cylindrical Shell is the Housing of the whole equipment, accessories, and components of the Water Tube Boiler.

- Man Hole

The Man Hole is a passway for the humans in the Boiler. The manhole will be utilized to clean, remove the dirt or dust in the boiler whenever maintenance is required.

- Chimney

The Chimney is the vertical pass-out construction that helps the combusted gases to escape from the Boiler.

- Safety Valve

The Safety Valve is one of the accessories (also mounting) in the Boiler. Whenever the pressure of the steam in the drum exceeds its capacity of baring then the Safety Valve will open up and releases the extra steam to decrease the pressure.

- Water Tubes

The Water Tubes are the metallic cylindrical tubes that help the water to flow.

- Grate

The Grate is the space where the coal is feed and combustion takes place in the Boiler.

- Feed Check Valve

The Feed Check Valve is one of the valves in the Boiler that helps to control the water feed and restricts the backflow of water into the pump.

- Hand Hole

Hand Hole is another pass-way hole (not as big as manhole); wherever any sudden requirement of cleaning or repairing, the hand hole will help the humans to open up and perform the required operations.

- Pressure Gauge

Pressure Gauge is one of the accessories (also mounting) of Boiler that helps to find the pressure of the steam producing in the boiler.

Note: Few more mountings, components can be seen in the shown image above.

The simple vertical boiler is constructed in such a way that the Water Tubes, Steam Space, Chimney are placed one over the other (observe the simple vertical boiler construction in the image) so, the combusted gas will escape from the boiler through Chimney easily.

2. Babcock And Wilcox Boiler:

The Babcock And Wilcox Boiler is an example of a Horizontal Straight Water Tube Boiler where the Water Drum is constructed at the top of the setup horizontally and feeds the water into water tubes.

There may be more than one water tube in the setup and we can observe that the water tubes are inclined around 10-15 degrees to the horizontal position (inclination helps the water for a proper circulation).

The few components and devices that are used in the Babcock and Wilcox boiler construction are as follows

- Water Drum

The Water Drum is the storage component of water where the water is taken to feed into the tubes.

- Safety Valve

The Safety Valve is one of the accessories (also mounting) of the Boiler that will help the boiler to release the excess steam and maintain the pressure levels of the Boiler.

- Steam Stop Valve

The Steam Stop Valve is one of the mountings of the Water Tube Boiler. It will restrict the steam flow from Water Drum to the Water Tubes or Vice Versa.

- Anti-Priming Pipe

The Anti-Priming Pipe is one of the valves that is used to prevent the flow of water particles that are contained in the steam. Usually, the Anti-Priming Pipe is around 1 to 2 meters in length; whenever, the steam with water particles trying to flow into the drum, the inertia of force in the pipe will restrict them and made water fall back again into the drum or pipes.

- Down Take Header

The Down Take Header is a tube that will connect the water drum to the water tubes to feed the water.

- Up Take Header

Up Take Header is the tubes that connect the steam drum and the water tubes. The up take header height will be more than the down take header as the water tubes are inclined.

- Damper

The Damper will restrict the flow of air into the Boiler

- Blow Off Valve

TheBlow Off Valveis one of the valves in the water tube boiler where it acts as a pressure level maintainer by releasing the excess steam into the surroundings.

- Baffle Plates

It helps to spread the hot gases uniformly over to the water tubes.

- Ash Pit

The Ash Pit is the space or area where the combusted coal or wood will convert into ash and collected in the pit.

Note: Few more mountings, components can be seen in the shown image above.

The water is feed into the water tubes from one end and the steam is passed out through another end into the same drum where the water is stored to feed. The steam that can be operated in Babcock and Wilcox Boiler will be between 11 to 18 bar at maximum.

3. Stirling Boiler

The Stirling Boiler is an example of a Bent Tube Boiler where the water tubes are constructed with many bents, and barrels are connected at the end of the water tubes.

The Stirling Boiler do consists of

- Mud Drum

The Mud Drum is a drum constructed at bottom of the water tube boiler. The undissolved and solid dust particles that are contaminated the water will be collected in the Mud Drum and removed later.

- Steam Off-Take

The Steam Off-Take will be the pass-way of the produced steam into the turbine for its working.

- Steam Drum

In the Stirling Boiler, there are three drums where one of them will be Feed by Water and called as Water Drum, another two are Steam Drums.

The water is feed into the water drum and water tubes receive water from water drums. The gases are introduced over the water tubes from one of the sides and leaves from the opposite side. Due to the gases, the water gets converted into steam and flows over into the steam drums.

These are the 3 important Water Tube Boiler Examples that are using in the Industries and Production Companies for their work.

Advantages Of Water Tube Boiler :

The advantages of water tube boilers vary according to its types; they may be similar in few conditions and differ in another so, the advantages of Water Tube Boiler Types are as follows

- The Water Tube Boilers can consume less area in the overall Plant.

- Water Tube Boilers are much efficient to give an output of 90 percent at most (efficiency).

- The steam production is quick compared to other types of boilers.

- The steam rate production is more.

- The Water Tube Boilers can be used in Small Scale Industries with low-cost capital.

- It is easy to perform maintenance activities.

- Due to the number of types of water tube boilers, there are lots of options to adopt the water tube boiler according to the requirement and output of the Client or User.

Disadvantages Of Water Tube Boiler:

Similar to the advantages of water tube boiler variations from one type to another; the disadvantages too vary. So, the disadvantages of Water Tube Boiler Types are as follows

- The water can create scales inside the tubes if there is no frequent maintenance. So, the maintenance should be performed very carefully which is cost effective.

- Commonly, the water tube boilers are intricate in designing so, it is somewhat complex to construct too.

- Due to its limited water tubes, it is limited to small capacity plants and requires more technology to use water tube boilers in high capacity plants.

Applications Of Water Tube Boiler:

The Applications of Boilers will depend upon the requirement, space, and output of the industry or plant. So, the applications of Water Tube Boilers are

- The applications of Simple Vertical Water Tube Boilers can be seen in Steam dependent Vehicles or Automobiles like Railways, Cranes, etc.

- The Babcock and Wilcox Water Tube Boilers can be seen in Thermal Power Plants due to their higher advantages.

- The Stirling Water Tube Boilers are used in the Sugar Refining Industries mostly due to their waste management system.

At most, the Water Tube Boilers are frequently using boiler types that can be found in various industrial applications.

Conclusion:

In the water tube boilers, the water flow increases its exposure to the fire mostly and results in fast conversion of steam. In few types of water tube boilers, the superheater is used to increase the steam quality (or saturation levels) for maximum efficiency. Additional to the efficiency, the safety features are also a considerable factor in the Boilers. So, applications of mountings in boilers can be one of the reasons for Safety.

Of course, there are different water tube boiler types and water tube boiler examples; which enlarges its applications according to the Industry requirement but there are a few applications and requirements that dominate the Water Tube Boiler and look for an alternate solution. This domination will be benefited by the Fire Tube Boiler and its usage.

Frequently Asked Questions

1. How does a water tube boiler work?

A Water Tube Boiler is simple in working. The feed water is forced (or naturally) sent into the water tubes from the water drum and let the flue gases flow over the tubes.

According to the contact of water to the tubes and flue gases to the tubes, the water reaches a certain level of temperature and converts into steam.

So, this is the simple working of a water tube boiler.

2. Why water tube boilers is more efficient?

The water tube boilers are more efficient because

- Due to the water flow in the tubes, the water will convert into steam as quickly as it can (it is because of less quantity of water).

- There is a chance of increasing the quality of steam by utilizing the superheaters.

3. Where are water tube boilers used?

The water tube boilers can be used at many places where high-temperature liquid or steam requirements take place. Few of them are

- Water Tube Boilers are used in Printing and Packing Companies

- They are used in Sugar Refineries.

- Water Tube Boilers are used in Power Plants and many more.

4. Why we use water tube boilers?

The Water Tube Boilers are one of the types of boilers and the purpose of using them are

- For high efficiency and to produce a quality of steam rate.

- For increasing the temperature of the liquids in Medium Scale Industries for its operations.

- To save the construction space in the Plants.

5. What are the 3 types of water tube boilers?

The three types of water tube boilers are

- Horizontal Straight Boiler

- Cross Bent Boiler

- Cyclone Fired Boiler

6. What is the example of Horizontal Straight Water Tube Boiler?

The Babcock and Wilcox Boiler is one of the examples of Horizontal Straight Water Tube Boiler and it is designed by the American Firm called Babcock and Wilcox which is named after it.

7. What is the example of Bent Tube Boiler?

The Stirling Boiler is an example of a Bent Tube Boiler. These are large in size and mainly used in refineries, power stations, etc.

8. What is a Bent Tube Boiler?

The Bent Tube Boiler is a type of water tube boilers where the water tubes are designed in a zig zag structure and connected to the water drum on one side and steam drums on the other end.

9. What is Grate in Boilers?

The Grate is the space allocated in the boiler to feed the coal and combust them to produce the fire gases. Mostly, it is located at the bottom of the water tubes and water tube boiler. So, it could be easy to send the gases over to the water tubes without any external force.

10. What is Anti-Priming Pipe in Boilers?

The Anti-Priming pipe is the pass-way pipe of steam from the water tubes. It will restrict the water particles in the steam to enter into the steam drum or further section. We can observe this pipe in the Babcock and Wilcox Boiler.

11. What is Blow Off Valve in Boilers?

The Blow Off Valve is one of the mountings and safety valves in the water tube boiler. Whenever the steam in the boiler exceeds the maximum limit, the blow-off valve opens up and releases the excess steam into the atmosphere.

12. What is Damper in Boilers?

The Damper is one of the air-flow restricting sections or components in the Babcock and Wilcox Boiler. It will stop the air to enter the boiler unnecessarily.

13. What is Up Take and Down Take Header?

Up take and down take headers are the tubes used in the Babcock and Wilcox Boiler.

Up take Header: The Up take header is the tube that connects the water tubes with the steam drum and helps to transfer the steam from water tubes into the steam drum.

Down Take Header: The Down Take Header is the tube that connects the water drum and one of the ends of the water tubes. It helps to feed the water into the water tubes.

14. What is Feed Check Valve?

The feed check valve is a mounting in the water tube boiler that will help to

- Control the amount of feeding of water into the boiler.

- Prevents the back-flow of water from the boiler to the pump.

15. What are the advantages and disadvantages of Babcock and Wilcox Boiler?

The advantages and disadvantages of Babcock and Wilcox Boiler are

Advantages:

- Can be used in medium-scale industries.

- High efficient.

- More Steam rate

Disadvantages:

- Require Skilled Labours.

- Chances of producing scales in the water tubes which is difficult to prevent.

- Need proper supervision.