What is A Thermocouple & Types of Thermocouples?

A Thermocouple or Types of Thermocouples are Electrical Devices, which is also called as Thermal Junction, or Thermoelectric Thermometer, or Temperature Measuring Sensor where it is used to sense the temperature at a specific point in the form of Electro Magnetic Force or Electric Current. The main principle that involved in the working of thermocouple is Seebeck Effect or Thermoelectric Effect; which is the concept of electromotive force.

Thermocouples can sense the temperature due to its two dissimilar electrical conductors (mainly wires) that are connected at an Electrical Junction, also called as Thermal Junction. When the junction of these two metal wires or electrical conductors is heated or cooled, a voltage is produced, which can be correlated back to temperature, based on the phenomenon of the thermoelectric effect, which is a difference in temperature can be converted to electric voltage.

Also Read:

- 3D Printing Machine – Working, Advantages, Disadvantages, Applications and FAQ’s

- Types of 3D Printing Machine – Their Working, Advantages, and More

Different types of thermocouples can be used in various industrial applications called as commercial thermocouples, homes, offices, and, daily equipment, as well as in manufacturing, machining, automobile components or engines, (two stroke or four stroke) and scientific applications. Thermocouples are manufactured in a variety of styles, such as thermocouple probes, thermocouple probes with connectors, transition joint thermocouple probes, infrared thermocouples, bare wire thermocouples or even just wire thermocouples because thermocouples are very simple, robust and cost-effective sensors. These thermocouples are standardized against a reference temperature of °C. Practical devices use electronic methods of cold-junction compensation to accommodate varying temperatures at the equipment terminals.

Table of Contents

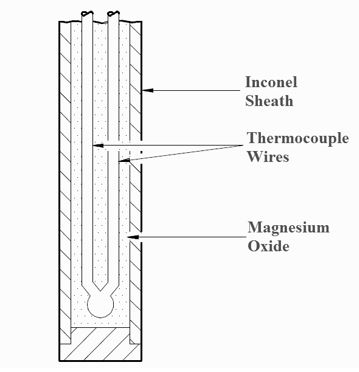

Construction of A Simple Thermocouple

The construction of the Thermocouple is very simple as shown in figure below but involve few electrical principles. It consists of two separate metal wires that are joined together at the junction. Junction ends are classified into three types

- Ungrounded

- Grounded and

- Exposed Junctions.

1. Underground junction

In this underground-junction the conductors are completely separated by a protective cover. The applications of this junction mainly include high pressure application work. The main advantage of using this function is to reduce stray magnetic field effects.

2. Grounded-junction

In a grounded-junction, the metal wires and the protective cover are connected together. This function is used to measure temperature in acidic environments and it provides resistance to noise.

3. Exposed-Junction

The exposed junction is applicable in areas where quick response is necessary. This kind of junction is used to measure the temperature of a gas. The metal used to make the temperature sensor basically depends on the measured range of temperature.

Also Read:

- Electrical Bicycle – Working Principle, Advantages, Disadvantages, Applications and FAQ’s

- Types of Electrical Bicycle – Working, Advantages, and More

Commonly, a thermocouple is designed with two separate metal wires, such as iron and constantan (an alloy consists copper and nickel), that connect at a junction called a hot junction to the locating element. This consists of two junctions, a junction connected to a voltmeter or transmitter where the cold junction and the other junction are connected in a process known as a hot junction.

Different Types of Thermocouples

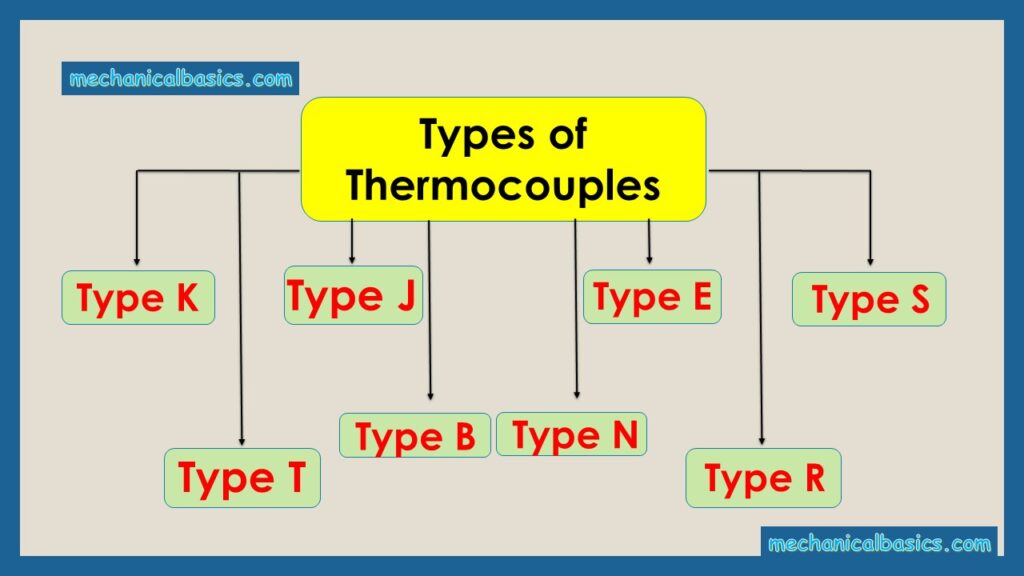

Thermocouples are available in different types, according to the variety of combinations of alloys. The type of thermocouple is selected according to the application, cost, availability, stability, chemical properties, output and temperature range. The Types of Thermocouples are

- Type K Thermocouple

- Type T Thermocouple

- Type J Thermocouple

- Type E Thermocouple

- Type N Thermocouple

- Type S Thermocouple

- Type R Thermocouple

- Type B Thermocouple

Let us read about these types one by one

Type K Thermocouple

- The K-type thermocouple is the most common type of thermocouple, and has the widest temperature measuring range.

- The Positive Lead of a Type K thermocouple is composed of approximately 90% Nickel and 10% Chromium. The Negative Lead of the Type K Thermocouple is composed of approximately 95% Nickel, 2% Aluminum, 2% Manganese, and 1% Silicon

- Positive Lead can be seen in yellow, which is a non-magnetic material; while the Negative Lead will be in red and is a magnetic material. Furthermore, the overall jacket will be in yellow.

- The K thermocouple type has a temperature range of -200˚C to +1260˚C (-328 F to +2300 F).

- It is inexpensive and is widely used in general purpose applications where temperature sensitivity around 41μV/C is required.

- The accuracy of the K thermocouple type is ±2.2 C% (0.75%). The accuracy of thermocouples also depends on the deviations in the alloys.

Type T Thermocouple

- The Type T Thermocouple is suitable for low temperature measurement. The positive lead is made up of Copper and the negative lead is of Constantan Material (an alloy consists copper and nickel).

- The composition of both substances are around 45% Nickel and 55% of Copper.

- The sensitivity of type T thermocouple is 43 µV/°C. This thermocouple is suitable to work in oxidizing environment.

- The temperature ranges of this thermocouple ranges from -200 °C to 350 °C.

Type J Thermocouple

- Positive lead of Type J Thermocouple is made up of iron and negative lead is made of constantan (an alloy consists copper and nickel) with a composition of 45% nickel and 55% copper

- The positive lead is white in color and the negative terminal is red in colour with overall jacket of black.

- The J thermocouple type has a temperature range of -210˚C to 750˚C (-346F to 1400F).

- These types of thermocouple have a shorter temperature range and a shorter life span than a K Type thermocouple.

- The J type of thermocouple has an accuracy of ±2.2˚C (0.75%).

- The sensitivity is about 50μV/˚C. So these thermocouples are not recommended for low temperature applications.

Type E Thermocouple

- This type of thermocouple has higher accuracy and strong signal compared to K and J type over medium temperature range. It is more stable thermocouple compared to type K and type E with higher Electro Magnetic Force per degree Celsius.

- The positive lead is composed of nickel-chromium (90% nickel and 10% chromium) while the negative is composed of the terminal constantan (95% nickel, 2% aluminum, 2% manganese, and 1% silicon).

- The Positive Lead is purple in color and negative lead is red in colour.

- The temperature range for type E thermocouple is between –270˚C to 870˚C (454 to 1600F).

- The standard accuracy is about ±1.7˚C%.

- Type E Thermocouple cannot be used for vacuum or low oxygen applications and sulfuric environments. The cost of E type thermocouple is more than J and K type thermocouple.

Type N Thermocouple

- The Type N thermocouple was designed and developed by the Defense Science and Technology Organization (DSTO) of Australia by Noel A. Burley.

- The accuracy and temperature range of a Type N thermocouple are the same as that of a Type K thermocouple.

- The temperature range of N type thermocouple is between -270 °C and 1300 °C.

- The sensitivity is slightly lower than the K thermocouple type and is 39μV/˚C.

- The Type N thermocouple is composed of Nicrosil Positive Wire and Nisil Negative Wire. The Nicrosil is a mixture of Nickel, Chromium and Silicon whereas; Nisil is a mixture of Nickel and Silicon.

- Type N thermocouple are the best alternative of type K thermocouple for low oxygen condition. This type of thermocouple is use in vacuum, oxidizing environments, inert environments or dry environments.

Type S Thermocouple

- Type S Thermocouples are generally used for high temperature applications due to the high accuracy and stability, sometimes it is also used for low temperatures.

- The temperature range of S type thermocouple is between 630 °C to 1064 °C.

- The Positive Lead of S Type is made up of 90% Platinum, 10% Rhodium and Negative Lead is made up of Platinum.

Type R Thermocouple

- The Type R thermocouple is made of platinum and rhodium. The output range and stability of the Type R is slightly higher than that of Type S thermocouple.

- The Positive Lead of Type R thermocouple is composed of 87% platinum and 13% rhodium and negative lead is made of platinum.

- The temperature range for Type R thermocouple is between 0 °C to 1600 °C.

Type B Thermocouple

- The Type B Thermocouples are made from a combination of platinum and rhodium.

- The positive lead of the thermocouple is composed of 70% platinum and 30% rhodium and the negative lead is composed of 94% platinum and 6% rhodium.

- Type B thermocouples are used to measure temperatures up to 1800 °C.

- The output of this thermocouple is less than that of type R and S thermocouples. It can be used to measure temperatures up to 1850 °C.

Working Principle of Thermocouples

To understand the working of thermocouple we need to understand three effects or three concepts that responsible for the working of Thermocouple. They are namely

- Seebeck Effect

- Peltier Effect and

- Thompson effect

1. Seebeck Effect

As the working principle for thermocouple is based on these effects. In 1821, the German-Estonian Physicist Thomas Johann Seebeck was working on a project and observed that “when a conductor was subjected to a thermal gradient, it would generate a voltage”, which is later named as the thermoelectric effect; also known as the Seebeck effect.

This type of effect occurs between two dissimilar metals. Whenever heat is offered to one of the metal wires, electrons flow from the hot metal wire to the cold metal wire and we get a direct current in the circuit.

2. Peltier Effect:

Peltier effect is also a thermoelectric effect seen in electric circuits. It was discovered in 1834 by Jean Charles Athenais Peltier. Peltier found that “when current is made to flow through a circuit consisting of two different types of conductors, a heating/cooling effect is observed at the junctions between these two materials”, this change in temperature at the junction is the Peltier effect, which is quite opposite of the Seebeck effect. In simple words, temperature difference can be created by applying potential difference between any two dissimilar conductors.

3. Thomson Effect

The Thomson effect describes the “evolution or absorption of heat when an electric current passes through a circuit made of a single material with a temperature difference along its length”. Since two different metals are stable together, if they form two joints then the voltage induces the total conductor length due to the temperature gradient.

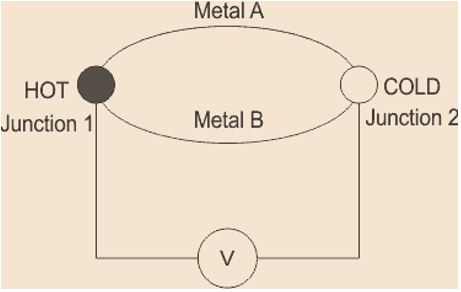

As we know thermocouple consists of two plates of different metals and both the plates are joined at one end to form a junction. The junction is placed on the surface where we want to measure the temperature and the other end of the plate is kept at a lower temperature. The first junction is also known as the hot junction and the second one is known as the cold junction or reference junction. If the circuit is closed, a very small amount of current will flow through the circuit. If we connect the voltmeter to this circuit, we can measure the voltage as a function of the temperature difference between two junctions and by measuring the voltage, we can calculate the temperature of the hot junction.

In the above diagram, we can see that the junctions are represented by P & Q, and the temperature is represented by T1 and T2. Electromagnetic force is generated in the circuit when the junction temperatures are different from each other.

Also Read:

- Thermoplastic Polymer – Types of Thermoplastic Polymer, Advantages, Disadvantages, Applications and FAQ’s

- Automobile Governors – Working, Advantages, Disadvantages, Applications and FAQ’s

Advantages of Types of Thermocouples

The advantages of Types of thermocouples are

- The all types of thermocouples have High Accuracy.

- They are rigid and can be used rough and tough like high vibration environments.

- Thermal Reaction is faster.

- Temperature Operating Range of Thermocouples are wide.

- Cost is low and extremely consistent.

- The J Type Thermocouple is a low cost and most commonly used thermocouple.

- The J type of thermocouple is suitable for oxidation environment.

Disadvantages of Types of Thermocouples

The Disadvantages of thermocouples are the following.

- Thermocouples have Non-Linearity

- Minimum Stability

- Low Voltage

- Need References while working on real projects.

- The types of thermocouples are less Sensitive.

- Re-Calibration of the Thermocouples are hard

Applications of Types of Thermocouples

- In Steel Industry

We can use Type B, S, R and K thermocouples in steel and iron industries to monitor temperature and chemistry during the steelmaking process.

- In Manufacturing

Thermocouples are commonly used in the testing for prototype electrical and mechanical devices. As an example we can see, the switchgear test for its current carrying capacity have a thermocouple installed during a heat run test to confirm that the temperature raise at rated current does not exceed design Limit.

The Other Applications of Thermocouples.

- They are used as temperature sensors in thermostats in offices, homes, offices and businesses.

- They are used in industries to monitor the temperature of metals in iron, aluminum and metal.

- We can use them for cryogenic and low temperature applications in the food industry. A thermocouple is used as a heat pump to perform thermoelectric cooling.

- They can be used for temperature checking in chemical plants, petroleum plants.

- These can be used in gas machines to detect pilot flames.

- Type K thermocouples perform best in clean oxidizing environments. It is not recommended to be used under partially oxidizing conditions in a vacuum

- The S type of thermocouple is used in applications such as the pharmaceutical and biotech industries, where high temperatures must be measured with high accuracy.

Conclusion

Thermocouples are widely used due to their small size and fast response, as well as their ability to tolerate shock and vibration, which making them perfect for temperature control and measurement. Different types of thermocouples can be enclosed in a sheath to protect it from the atmosphere and reduce the chance of corrosion. Even though they are temperature sensors, they also work only up to a level of temperature limit. Furthermore, they do require some precautions, which improve their life, accuracy, and response.

Frequently Asked Questions

1. What is the Life Span of thermocouple?

Ans. We cannot precisely define the life span of a thermocouple it depends on the application where it is used, if we maintain it properly, it will last for years. But, after a few years of continuous use, maybe there will be an aging effect and because of this, it will generate weak output signal. The cost of a thermocouple is not very high. Therefore, it is advisable to replace the thermocouple after 2 to 3 years.

2. How can we measure thermocouple output?

Ans. The output of Electro Magnetic Force obtained from the thermocouple can be measured by using Multi-Meter, Potetiometer, and Amplifier with Output Device.

Multi-Meter – The multi-meter can be connected to the cold junctions of the thermocouple and the deflection of the multi-meter pointer is equal to the current flowing through the meter.

Potentiometer – With the help of DC potentiometer, the output of thermocouple can also be measured.

Amplifier with Output Device– The output received from the thermocouple is amplified through an amplifier and then fed to a recording or signal device.

3. What is the Resistance Test of Thermocouple and how to perform?

Ans. To know whether the thermocouple is working perfectly or not, we check the resistance test of the thermocouple device. To perform the resistance test, the device must be placed in a gas appliance line and the equipment required is a digital multi-meter and alligator clip.

Procedure for Resistance Test

- Connect the alligator clip to the section of the multi-meter. Clip on both ends of the thermocouple where one end will be folded into the gas valve.

- Now, turn on the multi-meter and note down the reading options. If the multi-meter displays ohms in short order, the thermocouple is in perfect working condition. Or when the reading is 40 ohms or more then it is not in good condition.

4. What is the Open Circuit Test of thermocouple?

Ans. Instruments used for open circuit test are alligator clip, lighter and digital multi-meter. Here instead of measuring the resistance, we calculate the voltage. Place a lighter with heat one end of the thermocouple, now use the multi-meter to check. If the multi-meter shows a voltage in the range of 25-30 mV, it is functioning properly. Or else, when the voltage is closer to 20mV, the device needs to be replaced.

5. What is the Close Circuit Test of thermocouple?

Ans. The equipment used in the closed circuit test are alligator clips, thermocouple adapters and digital multi-meters. The adapter is placed inside the gas valve and then the thermocouple is placed on one side of the adapter. Now, turn on the multi-meter. The equipment is in proper condition when the reading is in the range of 12-15 mV, when the voltage reading drops below 12mV, it indicates a faulty appliance.