What is Power Hacksaw Machine?

The Power Hacksaw Machine is a type of Automatic Machine Tool whereas; the whole purpose is cutting the materials (metal or non-metal) that consists less and even high thickness or diameter. The Hacksaw is a simple cutting tool operated manually that requires more effort.

The simple hacksaw that runs on electricity or power to cut the materials is called Power Hacksaw. The hacksaw or power hacksaw machine consists of a power hacksaw blade to cut the materials.

Also Read:

- Pipe Bending Machine – Parts, Working, Advantages, and Applications

- Water Jet Machining – Principle, Parts, Working, Advantages, and Applications

Parts Of the Power Hacksaw Machine:

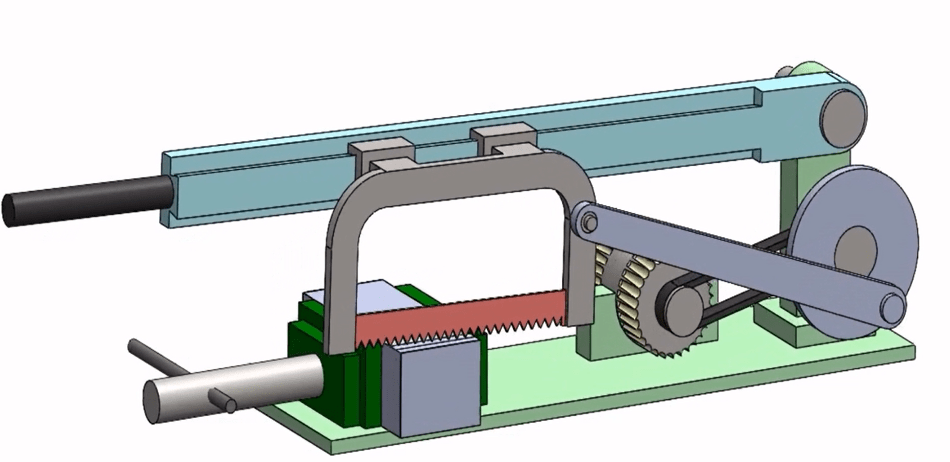

The machine and machine tool does consist of different parts and mechanism for its working. As the power hacksaw is an automatic machine tool; it requires a number of parts and a dedicated mechanism to achieve the purpose. So, power hacksaw machine parts are as follows

The Frame or Body or Base:

As we know, every machine and machine tool does consist of a frame or body to create a structure and dependency for the whole system. Similarly, the power hacksaw does consist of the base where the Power Hacksaw Blade Arm, Blade, Machine Vise, etc are rest and fixed.

DC Motor:

As the hacksaw machine is an automatic machine tool, it requires a source to run. The DC Motor is a Direct Current Electrical system that will convert Electrical Energy into Mechanical Energy we can say that the motor will utilize the electrical power to generate the magnetic flux between the coils and responsible for the revolution of the mechanical shaft.

Power Hacksaw Blade Arm:

The power hacksaw blade arm is the support for its blade that is fixed to the arm. The movement of the power hacksaw blade depends upon the arm itself.

Flywheel:

A Flywheel is a round and rotating component that is connected to the motor or gear output using a shaft. It will transmit the energy to the horizontal guide and also stores the energy according to the requirement.

Horizontal Guide:

The horizontal guide is a set that is connected to the flywheel and the power hacksaw blade arm. The horizontal guide is a hallow cylindrical component that will slide over a shaft smoothly.

Power Hacksaw Blade:

The blade is the component that does the cutting operation. It is thin and long in length with sharp cutting edges.

Switch on/off Power Box:

The switch on/off power box will help the operator to start and stop the operation of the power hacksaw machine according to his requirement.

Machine Vise:

The machine vise is the workpiece holding setup. To prevent the movement of the workpiece while operating the machine vise is used. We can place the workpiece in between the two slides and can be tightened using the screw movement.

Working Of Power Hacksaw Machine:

The power hacksaw working is very as simple as like construction. The motor runs by electricity and the mechanical power from the motor to the Flywheel is transferred using a mechanical shaft.

At this stage, to control the power or speed we can arrange an electrical system or different types of gears of different sizes. So, the belt connection that transfers the power from the motor to the gear can be changed to reduce and increase the speed.

- If the belt is connected between the motor and small gear then the output speed is more.

- If the belt is connected between the motor and large gear then the output speed is low.

According to it, the speed will be transferred to the flywheel which is connected to the horizontal movement setup. Due to the flywheel rotation, the horizontal setup will move back and forth which results in arm and power hacksaw blade movement.

Whenever a material (metal or non-metallic) is placed in the machine vise, the blade movement and feed will cut the material. This is the working of the power hacksaw machine which is simple and faster.

Although, the working of power hacksaw depends upon the electricity the working speed will depend upon the thickness of the material that required cutting.

- If the thickness or diameter of the material is more, then it is supposed to perform the operation (or cutting) at low speed for saving the blade for long life and preventing the power hacksaw blade damage or breakage.

- Similarly, we can run the power hacksaw at high speeds for less thickness materials whereas; it will not affect its blade and at the same time it can durable for many cycles.

Note: The cutting operation generates the heat and leads to the breakage of the blade; to prevent this, water is used as the coolant.

Advantages Of Power Hacksaw Machine:

The advantages of power hacksaw machine are

- The operation of power hacksaw is simple.

- The power hacksaw can cut the materials very fast even though the thickness or diameter is more.

- This type of machine tool can be operated at high speeds and even at low speeds.

- We can find a portable power hacksaw according to save working space.

- The power hacksaw machine blades are easy to remove and fix so, we use the different types of blades (according to the strength) for different types of materials.

Applications Of Power Hacksaw Machine:

A power hacksaw is a automatic machine tool that can be used in a vast area. Its applications are

- It is used in workshops where the high thickness and of materials are used to the machine.

- Being an automatic machine, the power hacksaw can be used in Automobile Manufacturing Industries.

- The applications of Power Hacksaw are mostly in large materials Welding industries or enterprises.

Conclusion:

In the earlier days, the hand hacksaw or simply hacksaw is used to cut the materials like wood, iron, plastic, etc. that consumes a lot of human effort and time. The consumption of more cutting time and effort will decrease the productivity of manufacturing things.

The power hacksaw machine is a time-saving and effort-saving invention that helps to increase productivity in manufacturing. The power hacksaw is not a cost-effective machine and can help organizations and individuals in cutting the materials.

Frequently Asked Questions:

The principle behind the power hacksaw machine is to convert the electrical energy of the DC motor into horizontal or linear reciprocating motion using a power hacksaw blade to cut the materials.

The type of motor used in the Power Hacksaw is DC Motor (Direct Current).

The main advantages of the power hacksaw machine are

- It is easy to operate

- Fast machining process

- Able to cut high thickness and hard materials.

- No risk involved

- No need for skilled labour

We can control the speed of the power hacksaw machine using the power controlling device or by adjusting the output gear. If the output gear is large then the output speed is reduced so; according to this, the speed of the power hacksaw machine can be controlled.

The Power Hacksaw can be used to cut any type of material whether it may be metallic or non-metallic material. Examples of non-metallic materials include wood, plastic, etc. metallic materials include iron, steel, etc.