What is Gravity Controlled Governor?

Gravity Controlled Governor is a type of Mechanical Governor or Centrifugal Governor. As this types of governors are worked with the principle of gravity, where the weight of the sleeves and balls will play the key role in its working so, it is called as Gravity Controlled Governor. Furthermore, this Gravity Type is classified into two types based on its construction and working. The two type of Gravity Type of Governors are

- Porter Type of Governor

- Proell Type of Governor

Let us read about these two types of gravity controlled governor in detail.

Table of Contents

What is Porter Governor?

Porter Governor is a sort of Gravity Controlled Governor, which is a type of Centrifugal Governor that has an additional center load on the sleeve to enhance the speed of the balls needed to raise the sleeve on the spindle. This will allow the governor to activate the mechanism and make the appropriate changes to the fuel supply. As a result, we can employ the this type of Governor at far greater engine speeds than the Watt Governor. It is a dead weight loaded governor that relies on gravity’s action. Porter is the updated version derived from the Watt governor.

Also Read:

- Watt Governor – Construction of Watt Governor, Parts of Watt Governor, Working of Watt Governor, Height of Watt Governor – Their Advantages, Disadvantages, Applications – And More

- Type of Electric Bicycle – Their Parts, Working, Advantages – And More

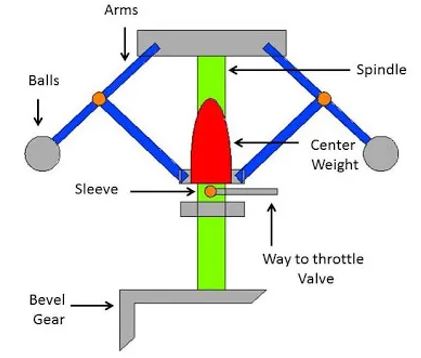

Construction of Porter Governor

This type of governor consists few parts that will be responsible for its construction, which plays key role in its working also. The parts of porter governor are

- Spherical Balls

- Arms

- Spindle

- Center Weight

- Sleeve, etc.

Porter Governor has two balls at the top, and the load is fastened to the sleeves. The bottom link is attached to the center sleeve, and there are two stoppers to regulate the movement of the sleeves. The throttle valve is controlled by a mechanism linked to the sleeves.

Working of Porter Governor

- Due to the spindle’s rate of revolution, the balls tend to move up and down on it.

- As the load on the engine reduces, the speed of the engine and spindle tends to rise.

- The upward movement of the balls is caused by centrifugal force, while the lower arm pulls the sleeves upward to drive the ball outward. These motions activate the throttle valve, reducing the fuel flow via the mechanism attached to the sleeves.

What is Proell Governor?

The Proell Governor is an another type of gravity controlled governor in which the fly balls are attached to the spindle by an extended arm. The fly balls are attached to this extra arm. Much like porter governor, this type of governor too has central weight that also increases the speed of rotation. It operates significantly more precisely than other governors and maintains a consistent function with no variation.

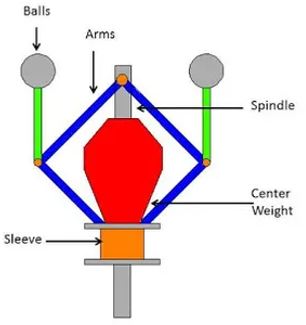

Construction of Proell Governor

This type of Governor consists few parts that will be responsible for the its construction, which plays key role in its working also. The parts of proell governor are same as the porter and they are

- Spherical Balls

- Arms

- Spindle

- Center Weight

- Sleeve, etc.

The spindle is linked to the engine, and its rotation speed increases and decreases as the engine (Two Stroke or Four Stroke Engine) speed changes. The spindle features a center load to boost the rotational speed.

Two arms are pivoted at the top of the spindle and are linked to the extended arms, which are linked to the fly balls. The other ends of the two arms that pivot to the top of the spindle are linked to the sleeve and move it up and down.

The sleeve activates a mechanism that allows the throttle valve to open and close. This sleeve contains stoppers at the top and bottom to restrict its movement.

Working of Proell Governor

When the load on the engine diminishes, the engine speed increases abruptly, as does the spindle rotation speed, since the spindle is linked to the engine. As the spindle turns faster, the arms pivoted to the top of the spindle rotate faster as well, and the balls travel outward due to increasing centrifugal force on the balls. When the balls travel outward, the sleeve linked to the arms rises and activates a mechanism that closes the throttle valve and reduces the fuel flow, lowering the engine speed. As a result, the engine speed is maintained.

Advantages of Types of Gravity Controlled Governors

The advantages of Porter Governor and Proell Governor

- The fundamental advantage of the Porter is that it can operate at higher Revolutions Per Minute (RPM) due to the dead weight load linked to the sleeve.

- The main advantage of proell type of governor is that due to the center load on the sleeve and the expanded links, the movement of the sleeve on the spindle is more accurate when the engine is operating at higher speeds.

- This types of governors are compact and smaller in size to use.

- The both type of governor has variable Torque.

Also Read:

- Automobile Clutch – Types of Clutches, Their Working, Advantages, Disadvantages, Applications – And More

- Bearings -Types of Bearings, Their Working, Advantages, Disadvantages, Applications – And More

Applications of Types of Gravity Controlled Governors

The applications of Porter Governor and Proell Governor are

- The Porter type of governor was used in older steam engines to adjust the speed based on load by restricting the fuel supply.

- The Proell type of governors are utilized to control the engine’s speed, which is due to the fact that the fuel-injected is dependent on the speed changes noticed along the shafts.

Conclusion

As it is already said that the Porter and Proell are developed to use at the High Speed to perform the accurate working conditions. This type of governors can control the torques due to the adjustable small weights.