What Is Four Stroke Engine?

The Four Stroke Engine is an Internal Combustion Engine and a type of power producing machine. The word Stroke means the maximum beat or a maximum movement that piston is allowed to reach. So, the 4 Stroke engine means that the engine works with the help of four different strokes or four different processes of piston to complete two revolutions whereas; Two Strokes Per One Revolution.

Four Stroke Engine is the most popular and using type of engine nowadays; it is famous for its efficiency and few other parameters. It is used in every Automobile includes Two Wheelers like Bikes, Four Wheelers like Cars, Vans, and even in Trucks used for transportation of Goods. Additionally, Four Stroke Engines are used in Generators, and Power Plants.

What is a Stroke?

The stroke is the maximum movement of the Piston in one direction; it means if the piston moves from upside to the downside then it is called One Stroke. In the Four Stroke Engine, the top most or maximum movement that piston moves upside can be called Top Dead Center (shortly TDC), and the maximum movement that piston moves downwards can be called Bottom Dead Center (shortly BDC).

What is a Process?

A process is the completion of a particular task in a period of time by following certain rules. So here, the piston does not move automatically without any action; it needs a certain process for its movement. Therefore, we can say that each stroke in the 4 stroke engine can be achieved by a process. So, we can say that there will be four strokes and four processes in the Four Stroke Engine.

It means, we can say that the piston moves from Top Dead Center to Bottom Dead Center with the help of a process and that movement is called the Stroke. At the same time, the thing that helps in achieving a stroke is called the Process. Both are interlinked and important points in 4 Stroke Engine.

Parts In An Engine:

The Four Stroke Engine consists of numerous parts and components but here are the main and important parts.

- Cylinder Block: It is the housing for the whole parts and components of a Fours Stroke Engine.

- Inlet/Suction Valve: It is used to suck the air from the atmosphere into the 4 stroke engine.

- Exhaust/Outlet Valve: It is used to send the gases from the system.

- Piston: It helps to perform the 4 Stroke Engine operations.

- Connecting Rod: It is the connecting part of the piston and crankshaft.

- Spark Igniter/Fuel Injector: To perform the combustion operation in 4 Stroke Engine.

- Crankshaft: It converts the to and fro motion of the piston into rotary motion.

Working Of Four Stroke Engine:

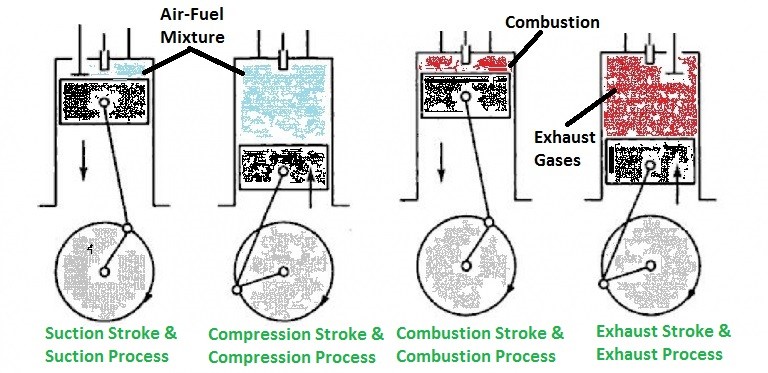

So, as told earlier; the Four Stroke Engine works with the help of four strokes or four processes to complete two revolutions. There are four different strokes and their responsible four processes for its working. They are

- Suction/Intake Stroke and Suction/Intake Process

- Compression Stroke and Compression Process

- Power Stroke and Ignition Process

- Exhaust/Outlet Stroke and Exhaust Process

Let us read about these four strokes and four processes in Four Stroke Engine in detail.

Suction/Intake Stroke and Suction/Intake Process:

The word suction is the process of intake the fluids (gases or liquids) into the system. The process of sucking the air into the system is called the Suction/Intake Process. Due to the suction process, the piston will move from top dead center to bottom dead center which is called the Suction/Intake Stroke.

The stroke is nothing but a movement so there will be no change in diesel engine and petrol engine but the process will be varies.

Suction Process in Diesel Engine:

In the Diesel Engine, the engine will intake (or suck) only pressurized air as its source. Due to this intake air the piston will move from top dead center to bottom dead center.

Suction Process in Petrol Engine:

In the Petrol Engine, the engines will intake (or suck) the Air-Fuel mixture as its source. Due to the intake of the air-fuel mixture, the piston will move from the top dead center to the bottom dead center.

Compression Stroke and Compression Process:

The word compression is the action of compressing the molecules (decreasing the volume of the system). As it means, the piston will compress the intake sources (air or air-fuel) from the bottom dead center to the top dead center. So, the process of compressing the source is called the Compression Process, and the movement of stroke from bottom dead center to top dead center is called Compression Stroke.

Compression Process in Diesel Engine:

In the Diesel Engine, the piston will compress the Air-Fuel mixture so it is called the Compression Process.

Compression Process in Petrol Engine:

In the Petrol Engine, the piston will compress the Air so it is called the Compression Process.

Power Stroke and Ignition Process:

As the name reflects, the Power stroke is all about producing the power using ignition (fire). The piston will be at top dead center and the fuel or spark will generate the fire in the top section and as a result the piston will move to bottom dead center. This movement from top dead center to bottom dead center is called Power Stroke and the process of generating the power is called Ignition Process.

Ignition Process in Diesel Engine:

In the Diesel Engine, the pressurized air is sucked into the system and it contains a Fuel Injector at the top. As soon as the compression process is completed, the system will achieve a great temperature atmosphere to generate the fire itself.

So, now to generate the fire, the fuel injector will release the fuel in tiny particles. As the system is ready to generate the fire, as soon as the fuel is released the fire will be produced and combusts fuel. Due to this, the engine will acquire great power and as a result, the piston will move from top dead center to bottom dead center.

Ignition Process in Petrol Engine:

As like Diesel Engine, petrol engine do not consist of any fuel injectors. Instead, petrol engines consist of Spark Ignitors that will release the sparks for the ignition process. At first, the petrol engines will suck the air-fuel mixture and at the end of the compression process, the system will acquire a good temperature to support the ignition process. As soon as the compression ends, the spark igniter will produce the spark and as a result, the combustion takes place. Due to this combustion, power will be generated and as a result, the piston will move from the top dead center to the bottom dead center. The process of combusting the air-fuel mixture is called the Ignition Process.

Exhaust/Outlet Stroke and Exhaust Process:

Now, the combustion process is completed and the fuel will be converted into gases. As we know that the piston is at the bottom dead center. To send the combusted gases to the outside, the piston will move from the bottom dead center to the top dead center which we can say Exhaust Process and the movement of the piston is called Exhaust Stroke.

So, the exhaust process in both the diesel and petrol engines is same.

Note: As the power generation in both the diesel and petrol engines can be developed only from one stroke Power Stroke (or Power Process) only and how this four strokes can be achieved without any external force?

The answer is here.

Of course, the power is generated by only one stroke but the generated power is not utilized fully for the power stroke instead, the engine will store a part of power in the Flywheel. The flywheel is the rotary component that fixed at the end of the crankshaft. Whenever the power is more than the consumption, this flywheel will store that extra power and utilize it for the next process or strokes.

So this is how the Suction Stroke/Process, Compression Stroke/Process, and Exhaust Stroke/Process can be achieved.

Also Read

- Advantages of Four Stroke Engine Over Two Stroke Engine.

- What Is Two Stroke Engine, Working of Two Stroke Engine – Parts, And Advantages.

Advantages of Four Stroke Engine:

The advantages of four stroke engines are

- The Efficiency of Four Stroke Engine is high.

- 4 Stroke Engine has good Mileage Economy.

- 4 Stroke Engines performance is higher than the other type of engines.

- The Emission rate is less.

Applications of Four Stroke Engine:

We can see the 4 Stroke engines regularly so the applications of four stroke engine are well-known to everyone. A few applications of four stroke engine are

- Four Stroke Engines are used in Compressors to compress the air and store it.

- Four Stroke Engines are used in the Generators to develop the Power.

- Four Stroke Engines can be used in the Thermal Power Plants.

Conclusion:

In the starting ear, the automobiles are used to work on the Two Stroke Engines but due to its limitations, the 4 Stroke engines are developed. We can see numerous automobiles around us and all those are Four Stroke Engines. The flywheel plays a crucial role in the Four strokes and four processes of the 4 Stroke engines.