What Is An Automobile Clutch?

The Automobile Clutch is one of the mechanical devices in the Transmission System of Automobiles (like Bike, Car, Truck, etc.). It is a device or set of several components that are connected next to the Flywheel (end of the engine). Moreover, Clutch and Types of Clutches act as mechanical linkage that are used to engage and disengage the driving shaft and pinion or driven shafts to transfer or prevent the power transmission that is developed by the Engine.

The Driving Shaft is the main rotating shaft that is connected to the Engine (the power developed by engine is supplied to the driving shaft) and the Pinion or Driven Shaft is another rotating shaft (observe the above image – Single Plate Clutch) that is connected to the Gear Box. As we know that, the rotation of any shaft is depends upon the torque developed by the source (or engine), and as the torque increases, the speed or rotation of the driving and driven shaft increases.

Also Read:

- Propeller Shaft – Its Function, Working, Advantages, And Applications

- Automatic Transmission System – Planetary Gears, Working, Advantages, Applications, And More

Table of Contents

What is Transmission System in Automobile?

The word transmission means that the transfer of something from one place to another. Similarly, the Transmission system is one of the useful systems in the Automobile vehicle where the engine power or kinetic energy (that developed by the engine) is transmitted to the driving wheels. It is an interconnected system of many devices and the series of the transmission system is as follows

Clutch – Gear box – Propeller shaft – Differential – Axles – Driving wheels

Now, let us start read about the parts, working principle, types of clutches, working, and their advantages.

Parts Of An Automobile Clutch:

An Automobile Clutch consists of many parts or components for its working so, a simple or regular clutch consists of following components and it may vary according to the type of clutches using in Automobile.

- Pressure Plate

- Disc or Friction plate or Clutch Plate

- Fingers

- Spacers

- Bushes

- Levers

These are the most important components utilized in the construction of a clutch.

Types of Clutches:

According to the speed of the engine developed, efficiency, and performance, there are different types of Clutches, they are as follow

- Single-Plate Clutch

- Multi-Plate Clutch

- Cone Clutch and

- Centrifugal Clutch

Working of Types of Clutches:

The working of Automobile Clutch vary according to its type because the construction is not similar, but the fundamental working is similar in all the 4 types of clutches.

- As the Function of a Clutch is to disengage and engage the driven shaft with the driver shaft so, to perform this function, an external effort or pressure is required, which is human effort.

- Whenever the driver of the vehicle pushes the Clutch lever, the pressure is applied on the pressure plate, then the pressure plate will push the friction plate (disc or clutch plate) backward direction, that is towards the driven shaft, which results in disengagement of the driven shaft with the driver shaft.

- So, this is the basic working of Clutch and its types. This working will be similar in single plate too.

Working of Single Plate Clutch:

This is one of the types of clutches and the working of single plate is the basic type and used in the starting era of Automobile.

- In this type of clutch, we can find one friction plate, which is connected to the Pressure plate adjoining to the Flywheel with the assistance of bolts.

- The friction plate has the property to regain its position when the pressure is removed. The friction plate or disc is aligned or constructed between the Pressure plate and Flywheel that is liberal to rotate.

- When the Force is applied on the Clutch Pedal, the disc will be disengaged with the Flywheel and no Transmission of Torque takes place between them.

- Whenever the transmission is disengaged, the driver can able to change the gear and after changing it, we can release the force on the Clutch Pedal, which is connected to Pressure

- After releasing, again the Disc Engages with the Flywheel automatically and transmission will take place.

Working of Multi Plate Clutch:

The working of multi plate clutch is as same as the working of single plate clutches. But in the multi plate, there are more than 1 friction plate (or clutch plat or disc), which then results in more Torque transmission.

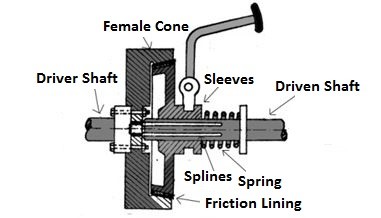

Working of Cone Clutch:

- The working of the cone clutch is also quite similar to single plate clutches and multi plate clutches.

- The Friction plate (or disc or clutch plate) will be Wedge-shaped, due to the wedge shape, the clutch is called Cone, and the hub is called as Female Cone, which is designed in a way that the cone can fix into it whenever the force is removed.

- As like the working of single plate and multi plate type of clutches, the working of cone clutch is also the same. Whenever the pressure is applied, the cone will be moved backward direction and the disengagement of the driven shaft with driver shaft is achieved.

Working of Centrifugal Clutch:

- The word Centrifugal is the force that tends the body to move away from its center. The working of centrifugal clutch is also similar to its meaning.

- In the other types of clutches, whenever the pressure is applied, the plate will move backward. Due to this backward movement, the strain over the driver shaft will be increased.

- So, to decrease the strain and to maintain the constant pressure force on the plates, the Semi-Centrifugal and Centrifugal Clutch will be used.

- The Centrifugal Clutch will exert an outward force on the plates and it makes the springs engage with the plate even at High Speeds.

Advantages of Types of Clutches:

The advantages of different types of clutches are as follows:

Advantages of Multi Plate Clutch:

Due to the presence of of multi plates in the multi plate type of clutch,

- The friction between the plates increases.

- The efficiency of a Clutch Plate also increases.

Advantages of Cone Clutch:

- The main advantage of cone clutch is to transmit the Torque by minimizing the losses in the single plate clutch and multi plate clutch.

- Due to this Wedge or Cone Shape, the transmission of Torque is high, which further acquires an excellent efficiency.

- The cone clutch is used in Off-Road Vehicles, Racing vehicles, and Powerboats.

Advantages of Centrifugal Clutch:

The centrifugal clutch is a specially designed clutch used for Lower Speeds and Higher Speed Conditions. The Pressure of springs on the plate will be exerted at Low speeds and these pressure force will increase with the increase of speed and these springs will help the plates to come backward movement.

Functions of An Automobile Clutch:

The Functions of a Clutch is limited but at the same time, it is prominent. The main functions of a Clutch are

- To engage and disengage the pinion shaft (or driven shaft) with the main shaft (or crankshaft) of the engine at different power transmission stages. By engaging and disengaging the clutch will help the automobile to achieve a smooth movement of torque.

- The functions of clutches also include controlling the speed of the automobile.

- In the manual transmission, the vehicle can be slow down by pushing and holding the clutch lever.

Conclusion:

The Automobile Clutch and different Types of Clutches are being more prominent in automobiles; the engagement and the disengagement of the driver shafts is necessary to change the gear ratio and to increase the speed. However, a few models without clutches developed and introduced in the market but they are not succeeded due to few faults. The different clutch types are developed to overcome the faults of their previous type.