What is An Automobile Governor?

An Automobile Governor is a Mechanical Mechanism or a Device that is used to determine and regulate the Automobile Engine Speed by supplying and preventing the Fuel to the required level. Automobile Governors and Types of Governors are also called as the type of feedback systems that is employed when there is a requirement to manage the variation of load in the system.

The primary function of all the types of governors are to manage the flow of gasoline into the engine in order to maintain a constant speed; hence, it is also known as a Speed Limiter.

Also Read:

- Electric Bicycle – Working, Advantages, Disadvantages – FAQ’s

- Types of Bicycle – Their Working and Many More

The basic principle of governor is that when the load on an engine grows, the engine speed reduces, which further require more fuel to be supplied to the engine. Similarly, when the load on the engine lowers, the engine speed increases. These are the situations where the types of governors come into play; increasing or decreasing the fuel flow to the engine based on the conditions. Precisely, the Automobile Governor functions as a mechanical bridge between the throttle of carburetor, which is in charge of fuel delivery and the speed

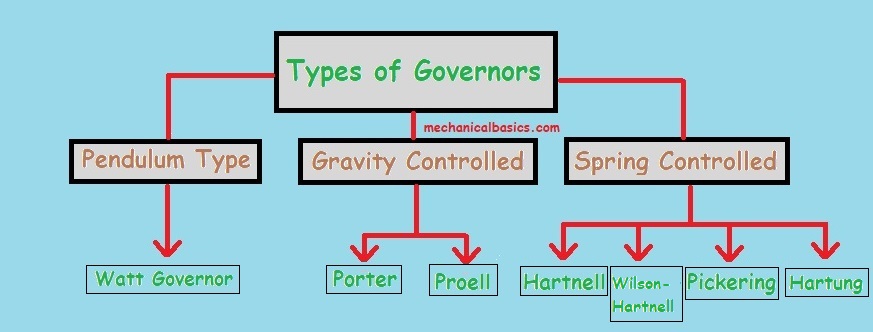

Types of Governors

As the Governors are being a part of Automobile since automobile existence. There are lots of changes in Automobiles and even in the Governors, which lead to different types of governors. These are mainly classified into Three types according to its construction, and working principle too

- Mechanical Governor or Centrifugal Governors,

- Hydraulic Governor, and

- Pneumatic Governor

Let us have look at these Governor Types in detail

Mechanical Governor or Centrifugal Governor

Mechanical Governor also called as Centrifugal Governor. In this type, mainly the centrifugal force and variations in speed are responsible for managing the operations of automobile governor. As we know the concept of Centrifugal Force, which means whenever the body is rotating, the force that developed will move outward direction of the axis. This is mostly utilizing governor due to the wide range of applications and is most easily employed when the mass balance is required in the automobile engine operation.

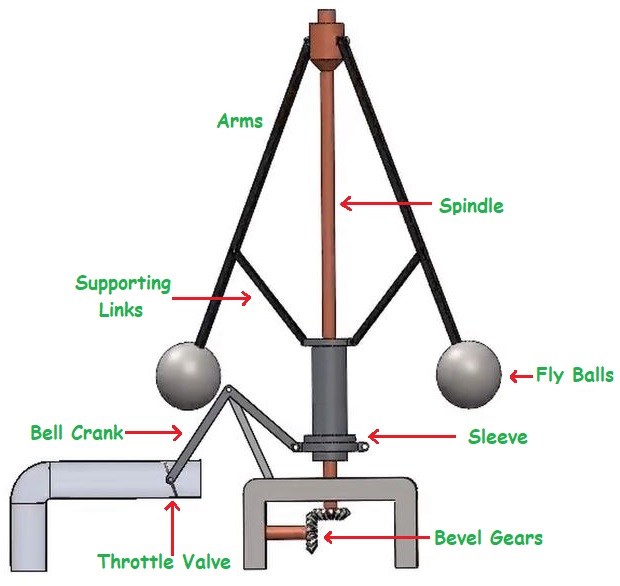

Construction of Mechanical Governor:

The Construction of a Centrifugal Governor is simple and easy to understand. To perform the governor operation, it requires few parts. They are

- Spindle

- Arms

- Supporting Links

- Bell Cranks

- Fly Balls

- Sleeve

These whole parts will be combined in such way that they can work according to the principle.

- This type of governor contains masses known as Governor Balls that revolve at a distance from the axis of a shaft and are powered by the engine crankshaft via adequate gearing, which is Bevel Gearing.

- The Balls are linked to the Arms by two balls of each and equal mass. These balls are linked by a mix of dead weight and a spring.

- The Spindle Axis is attached to the Sleeve and is powered by a bevel gear mechanism that is linked to the Crankshaft, due to which the bevel gearing rotates and further the centrifugal or mechanical governor too.

- The Throttle Valve is connected to the sleeves and is controlled by the engines speed change. As the load raises, the velocity of the ball and the governor, which is geared with the crankshaft decreases.

Centrifugal Governor or Mechanical Governor is further subdivided into two categories.

1. Pendulum Type of Governor

Watt Governor is the one and only one example in the Pendulum type of Mechanical Governor.

2. Spring Loaded governor/Spring Control Governor

There are four examples of spring control governor. They are

- Hartnell Governor

- Wilson Hartnell Governor

- Hartung Governor

- Pickering Governor

3. Gravity Loaded Governor

There are two types of gravity loaded governors, which we call as examples. They are as follows

- Porter Governor

- Proell Governor

Note: You will read every type of governor and their working video in the upcoming articles.

Working of Mechanical Governor:

- As said, the Centrifugal Governor work by balancing centrifugal force on rotating balls with an equal and opposing Radial Force.

- When the strain on the engine is reduced, the engine and governor speed up. As a result, the centrifugal force acting on the balls rises and the balls move radially outwards direction, due to which the valve in the carburetor will open and supplies more fuel to the automobile engine.

- The balls spin with the spindles, creating a centrifugal force in the inward direction, which is commonly referred to as the governing force. The variation in speed and centrifugal force supplied by the balls determines the regulating action. When the throttle valve of Carburetor opens, the flow of fluid rises, boosting the engine’s speed.

- Then the governor sleeve transmits the ball inward and upward movement to the throttle valve, which controls the quantity of gasoline given to the engine. When the shaft begins to rotate, the item begins to revolve around it and moves away from it owing to the action of centrifugal force, which activates the throttle valve.

Hydraulic Governor

Hydraulic Governor is one of the types of governor. Alike a Mechanical type, Hydraulic Governor is an all-speed governor, which means that the governor is in control during the entire rack and not directly by the accelerator to the supply to maintain the speed, regardless of the power that needs from moment to moment.

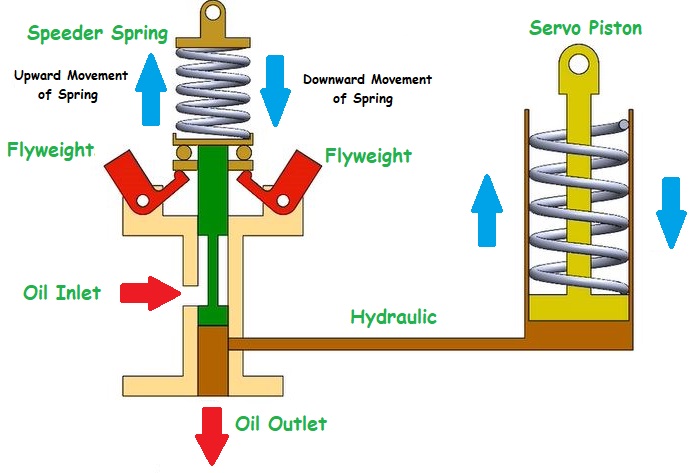

Construction of Hydraulic Governor

The Construction of Hydraulic Governor is not as easy as the Mechanical Governor due to the number of components involvement and its working principle. The construction of hydraulic type of governor consists

- Speeder Spring

- Fly Weights

- Oil Inlet

- Oil Outlet

- Servo Piston

- Hydraulic Oil

- Pilot Valve

You can see how the parts are constructed in the above image.

- The balanced mechanism of a hydraulic governor is connected to a control valve rather than the fuel that control racks directly, as in a mechanical governor.

- This valve is in charge of directing hydraulic fluid, which regulates the fuel racks and, as a result, the engine’s power or speed decreases and increases. Due to the increasing flow of fuel, greater force is created and vice versa.

Working of Hydraulic Governor

- The operational agent in a mechanical governor is the centrifugal force, but in the Hydraulic Governor, the pressure differential of the Hydraulic across an orifice is the operational agent in the Carburetor.

- In a hydraulic governor to pass the oil flow from a positive oil pump is operated by an Engine. The pressure differential varies in proportion to the square of the engine speed. At equilibrium, it is governed by the driver’s foot pressure on the accelerator pedal.

- Hydraulic governors remove the drive’s strong mechanical forces bearing loads and potential torsional vibrations. As a result, they outperform mechanical governors.

- Once the load is increased, the Flyweights will lift the spindle and allows the hydraulic to flow into the piston.

- Now, the piston will move upwards and allows the throttle valve in the carburetor to open, which allows the more fuel to supply to the engine. Due to which the engine receives more fuel supply and able to overcome the load and increases the speed of the whole vehicle.

Also Read:

- 3D Printing Machine – Its Working, Advantages, Applications – FAQ’s

- Types of 3D Printing Machines – Their Working and More.

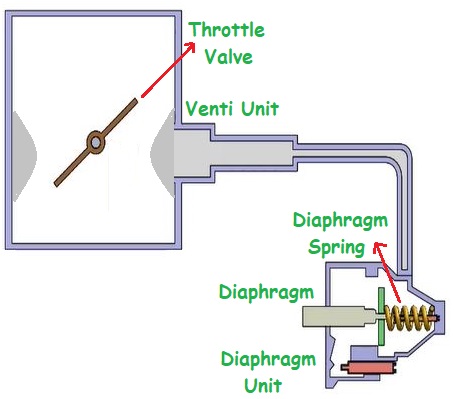

Pneumatic Governor

A Pneumatic governor, also known as flap valve governor is often employed to control fuel injection of an IC engine. Pneumatic Governor is an all-speed type of governor. It regulates an engine’s whole speed range. The Venturi effect governs the operation of these automobile governors. They respond to the velocity of air in the engine’s intake manifold.

Construction of Pneumatic Governor

The pneumatic governor is composed of two major components.

- Venturi Section Attached To The Air Intake Manifold – This portion monitors the airflow velocity and generates a vacuum based on it. It has a butterfly valve attached to the accelerator pedal.

- Diaphragm Unit Installed On The Fuel Injection Line – A diaphragm device installed on the end of the fuel pump can manage the fuel delivery based on the rise or decrease in vacuum created by the Venturi Unit. A spring is attached to one side of the diaphragm, while a control rod is attached to the other.

Other than these two major components, there are other different parts like

- Diaphragm Unit

- Diaphragm

- Diaphragm Spring

- And Few others

The Pneumatic Governor is directly connected to the Carburetor. Whenever the load is increased and there is requirement of more fuel supply; the pneumatic governor creates the vacuum and able to open the throttle valve. Due to which the valve opens and allows the more fuel to supply into the injector or engine.

Working of Pneumatic Governor

- The velocity of airflow in an engine’s intake manifold varies with engine speed. When the engine is stopped, the spring pushes against the diaphragm, keeping the fuel supply entirely open, that is maximum fuel supply position. When the engine is operating, the vacuum generated determines the location of the diaphragm and hence the fuel delivery.

- As the engine speed increases, the load on the engine lowers. The bigger the air intake, the greater the engine speed. This raises the suction generated by the Venturi section installed on the intake manifolds.

- The vacuum formed in the venturi portion drew the diaphragm and control rod together, which leads to immediate cut off of the gasoline supply. This reduction in fuel supply gradually reduces an engine’s speed.

- When a motor vehicle’s accelerator pedal is pressed, the butterfly valve opens, allowing more air to flow through it. It does, however, reduce airflow via the auxiliary venturi device, which controls fuel delivery that results in more fuel supply. Likewise, depressing the accelerator closes the butterfly valve while increasing airflow via the venturi unit which results in less fuel supply.

Advantages of Types of Governors

The advantages of Mechanical Governors

- This type of automobile governor is type of cheap.

- They can be used at any type of speed and load.

The advantages of Hydraulic Governors

- They provide a high output power.

- They have a high level of accuracy and precision.

- They are highly efficient.

- Hydraulic governors are simple to maintain.

- This type of automobile governor is used in medium to large size engines.

- Hydraulic governor has low-cost and basic and basic design.

The advantages of Pneumatic Governor are

- It has an Outstanding sensitivity.

- Pneumatic governors have shown to be most effective in small and medium-sized engines.

- They are sensitive to torque loading fluctuations and provide reliable idling control.

Disadvantages of Types of Governors

The disadvantages of Pneumatic Governor are

- Hydraulic governors are oversensitive at higher speeds. This might result in an abrupt shift in engine torque.

- This type of automobile governors may sometimes cause leakage.

- The density of the air influences the flow velocity.

Applications of Types of Governors

The applications of other types of governor are

- The Mechanical governor type is mostly observed in the Automobiles like Bikes, and Cars.

- The Hydraulic Governors mostly found in ships.

Applications of Centrifugal Governor are

- It restricts the rotation speed of an automobile’s internal combustion engine and maintains it controlled at the required pace.

- In a hydroelectric power plant, it is utilized to control the speed of the turbine shaft.

- Centrifugal governors are also employed to control the electromechanical music box’s speed.

Conclusion

Governors are control devices that operate on the feedback control concept. When the load on the prime mover varies, their fundamental job is to keep the speed within limits. They have no influence over the cycle’s speed modification. Governors, for a long time, have been a part of automobile vehicles. In near future, some governors can be replaced by the new technology and digital governor.

Frequently Asked Questions:

How is Flywheel different than a Governor?

A flywheel’s job is to manage the speed fluctuation caused by variations in the engine turning moment throughout each cycle of operation. The flywheel has no influence on the quality or amount of the operating fuel.

The governor’s function is to control the fluctuation of speed caused by variations in load over time. The governor has authority over the working fuel’s quality and amount.

Where is the mechanical governor fitted in the diesel engine?

A mechanical centrifugal governor is an important element of the injector pump in most diesel engines. This is also true for diesel engine hydraulic and vacuum governors. It is normally installed at one end of the engine block, usually the driving end. It needs a power take-off from the crankshaft, which is normally accomplished by the timing gear.

Why are not governors used in gasoline engines?

Mostly in the case of petrol engines such as motorcycles, scooters, and so on, the fuel is controlled using an accelerator. The accelerator serves the same purpose as a governor in a diesel engine. When you apply greater force, the fuel timing mechanism automatically injects more fuel into the cylinder’s combustion chamber.

It’s not that a gasoline engine lacks a governor. It is present. ECM controls both quality and quantity in contemporary MPFI and GDI petrol engines.

What is an Electronic Governor?

An electronic governor allows the engine speed to be adjusted from no-load to full load. It is made up of a Controller, an Electro-Magnetic Pickup (MPU), and an actuator (ACT) to perform speed control and regulation. The MPU is a magnetic field-powered micro-generator.