What is Agile Manufacturing?

Agile Manufacturing is an approach that focuses on maintaining high quality norms and the total cost involved in producing a particular product in order to meet the requirements of the guests. The Agile Methodology Process involves elements like Modular Design, Information Technology, Corporate Partners, and Culture of Knowledge. This approach is intended for companies operating in a largely competitive terrain, where small changes in product performance and delivery can make a big difference to a company’s long-term survival and character with consumers.

- Faced with a competitive request, artificial manufacturers are poised to borrow new strategies and technologies to ameliorate product quality, reduce manufacturing costs, and dock product lead times. Nimble Manufacturing is primarily a business conception. It is veritably simple to put your business in front of your main challengers.

- Nimble Manufacturing can be defined as the capability to survive and thrive in a competitive terrain of constant change and unpredictability by responding snappily and efficiently to ever-changing changes driven by products and services designed for guests.

- It is also important to know about Lean Manufacturing, which is a fast growing and efficient method in the world of competition. Lean manufacturing is employed to continuously eliminate waste in manufacturing to improve efficiency and productivity.

- The main focus of lean manufacturing is to meet high quality and low cost customer demands. This technology not only identifies the causes of waste, but also assists in its removal through identified principles and guidelines.

Conception of Agile Manufacturing is a business model that makes an association vulnerable to damage from changeable events and changing circumstances. This is achieved because the association is able of replying and conforming snappily.

The coming surprises of the future won’t make a nimble company vulnerable because that company will have formerly put in place a set of business practices, association-wide culture changes, and technology that will enable it to be prepared for any change in circumstances, request forces and client requirements.

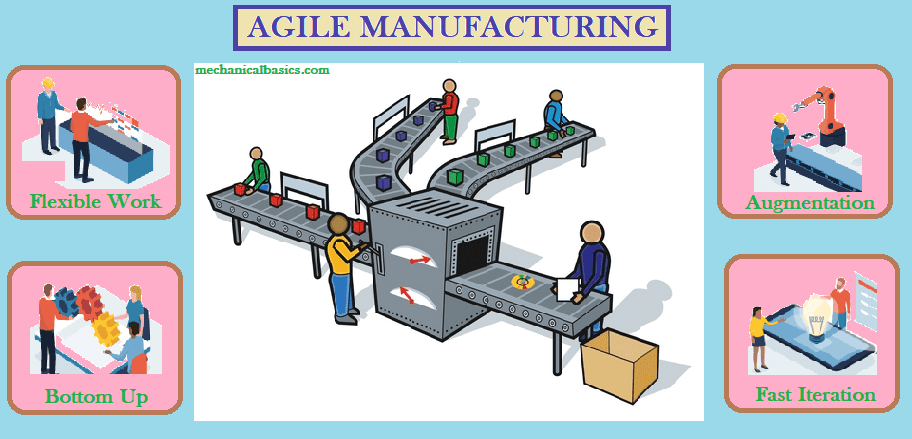

Agile Methodology Process is combination of speed and inflexibility that is hard to achieve. Companies using Agile Methodology Process will be

- Able Respond faster to changes in client demand.

- They will be suitable to take advantage of the windows of occasion that come up in the request from time to time.

With Agile Manufacturing Methodology, it is possible to develop new ways of interacting with guests and suppliers. Guests won’t only be suitable to pierce products and services, but they will be suitable to fluently assess and exploit edge, allowing them to use these abilities to achieve what they are looking for.

Also Read

- What is Six Sigma – Lean Manufacturing – Its Applications – And More

- Nano Technology- Types – Applications – And More

History And Evolution Of Agile Manufacturing Methodology

In 1990s, industry leaders were attempting to set a new paradigm for successful manufacturing enterprises in the 21st century. In 1991, a group of over 150 industry executives participated in a study. However many manufactures still struggled to implement lean production concepts.

About a decade ago, the agile manufacturing paradigm was created in response to a constantly changing new frugality and as a base for returning to global competitiveness. While dexterity means different effects to different businesses in different surrounds, the ensuing rudiments capture its essential conception.

We must be responsible for the responsive manufacturing of mass-customized, high- quality, client- valued goods/services, and by delivery; nimble enables you to repel non-stop and changeable change. Organizational Structure conforming knowledgeable empowered pool and an information structure that links actors to factors in an Electronic Network.

With the rapid change in customer demand, the manufacturer must adapt so as not to fall short. Survival will depend on your ability to maintain continuous and unpredictable change. This can be described as how snappy the environment can be. By being Agile, the company can initiate new innovations while simultaneously exploring new opportunities.

In agile production, if a product’s shelf life ends prematurely, the system is quickly redesigned and modified for the new, different product rather than shutting down the system or postponing the process, the ongoing evolution of the work plant is not affected. With things that you can’t control these things that an agile competitor to be successful must not only understand the current market and customers must also understand the potential for the future.

Key Elements of Agile Manufacturing

Agile Manufacturing Techniques or simply Agile Manufacturing consist Four Key Elements. They are

- Modular Product Design

- Information Technology

- Corporate Partners

- Culture of Knowledge

1. Modular Product Design

Design Products in a modular way that allows them to serve as platforms for faster and easier change. Modular Product Design is an approach that is used to design different products or applications by breaking them down into separate or independent parts. These different parts can be used for similar functions on different systems or machines.

A creative leader chooses an ideal modular design for their products because of its many benefits to designing products by integrating or assembling small and independent parts together to form a complete product.

2. Information Technology

Automate the rapid spread of information across the enterprise to enable ultra-fast response to orders. Information Technology (IT) is any use of computers, storage, networks and other physical devices, infrastructure and processes to create, process, store, secure and exchange all types of electronic data. Unlike technology used for entertainment or personal purposes, Information Technology is typically used in the context of business operations.

3. Corporate Partners

Create short-term virtual alliances with other companies that allow for better time-to-market for selected product segments. A corporate partnership is a mutually beneficial relationship between a for-profit company and a not-for-profit organization. This relationship can be a continuous association, however, usually with a focus on a specific event. It usually involves a charity receiving money, goods or services that the corporate partner considers beneficial.

4. Culture of Knowledge

Invest in the training of employees to achieve a culture that supports rapid change and continuous adaptation. It is the domain of an organization in which its values, beliefs, and behavioral norms determine the effectiveness and efficiency with which knowledge is exploited and used to achieve competitive advantage.

Characteristics of Agile Manufacturing

Manufacture’s that are agile competitors demonstrating these principles or characteristics. The four Agile Manufacturing Principles are

- Organize To Master Change

- Leverage The Impact Of People And Information

- Collaboration To Improve Competitiveness

- Enrich The Customer

1. Organize To Master Change

An Agile Methodology Process Company organizes itself in a way that allows it to thrive in change and uncertainty. In an agile business, human and material resources can be quickly realigned to adapt to a changing environment and market opportunities.

2. Leverage The Impact Of People And Information

In an agile business, knowledge is valued, innovation is rewarded, and authority is distributed to the appropriate levels of the organization. The administration provides the resources that are in individual need. The organization has an entrepreneurial spirit. There is an atmosphere of mutual responsibility for joint success.

3. Collaboration To Improve Competitiveness

Collaboration both internally and with other companies is the preferred operational strategy of an agile competitor. Their goal is to bring products to market as quickly as possible. The necessary resources and skills are found and used wherever they exist. This may involve partnering with other companies, possibly competitor companies, to create virtual companies.

4. Enrich The Customer

Customers perceive that an agile business significantly enriches them, not just itself. An agile company’s products are perceived as solutions to customer problems. The price of the product can be based on the customer rather than the cost of manufacturing.

The list of four agile principles indicates that agile construction involves more than just construction. It includes the organizational structure of the business, includes the way the business deals with people, includes partnerships with other organizations, and includes relationships with customers.

Also Read

- Powder Metallurgy – Its Preparation, Advantages, Applications – And More

- What is 3D Printing – Its Working – Type – And More

Design Strategies for Agile Manufacturing

- Vision- grounded flexible corridor- confluent systems.

- The preface of “Spurs” within the conveyor system.

- The use of modular worktables supporting specialty Fixturing and Tooling.

- Multipurpose and Modular End-Of-Arm Tooling.

Flexible Parts Feeders

- While inflexibility encompasses every part of a work cell design, including control tackle and software, the capability to feed corridor in a variety of shapes and sizes is critical. Conventional feeding styles similar as vibratory coliseum affluent are impracticable for flexible worksheets due to their specific nature.

- When performing a new or separate assembly, the corridor related to the new assembly must be fed without the time-out needed to design, acclimate and install a new feeding system.

- There is several flexible parts affluent on the request moment. The flexible affluent correspond of three conveyors working in musicale.

- The first conveyor is inclined and used to lift corridor from a bulk caddy in an effective manner. By conforming the cock angle, belt speed and belt material, the performance of the cock conveyor can be changed. This vertical conveyor belt terminates in a lined window within reach of the robot.

- A camera located above the stressed window is used to place the corridor on the conveyor. The robot can also take the corridor out of the carrier to assemble them.

- Operating the vertical conveyor at an advanced speed than the grade conveyor allows for lesser separation of corridor. The Corridor that is out of exposure or lapping is dropped onto a third conveyor, which returns them to the bulk hopper for-feeding.

Spurs and Worktables

- The conception of spurs and modular workbenches has been introduced to achieve inflexibility and effective use of space.

- The use of spurs makes better use of the robot’s limited workspace, while modular worktables allow devoted tooling and accessories to be changed snappily.

- Spurs both pallets and for modular work tables dislocated in predetermined places without the need for precise mechanical enrollment.

- Reference marks on pallets and art boards allow real equals to be calculated using computer vision.

- A recent enhancement to modular work tables is the preface of quick connection of electrical and curvaceous harnesses.

- A single air connection inventories air to a bank of solenoids mounted under the table. These solenoids control the entire outfit on the table.

- A 37- leg electrical outlet provides all power and signal lines to the solenoids and detectors on each table.

Agile Grippers

- The design of the gripper is an important aspect of achieving effective and dependable robotic part running.

- To optimize performance, clip designs must help minimize arm movement. Automatic tool changers are useful for quick metamorphoses to new assemblies, but for effective operation tool changes should be avoided during a given assembly.

- Whenever possible, multiple grippers should be used on a single curvaceous rotary wrist to minimize arm movements and avoid tool changes.

Design For Agile Manufacturability

- The nimble work cell must be able of designing new products.

- Design for Manufacturing teaches that the commerce of the factors in a product is abecedarian to successful automated assembly.

- For illustration, reducing the forces demanded to assemble a product simplifies the tackle demanded.

- Likewise, the free handedly tolerance slept corridor and cam design make them less sensitive to tone alignment and position trip wherever possible. Simple changes to the product in the early design stages can frequently have a significant impact during final product.

Advantages of Agile Manufacturing Process

The advantages of Agile Manufacturing Process are

- The company has a competitive advantage as it is continually changing its focus to satisfy its customer.

- Innovative designs are provided based on customers. This, in turn, provides a wider variety for the customer to choose from.

- Quickly respond to emerging crises.

- Even though production may change quickly, mass production can still be achieved while flexibility is still possible.

Disadvantages of Agile Manufacturing Process

The disadvantages of Agile Manufacturing Process are

- The sudden demand will cause shortages. Meanwhile, if the demand for products with a high production rate drops sharply, this could lead to a number of products that could not be sold.

- In order to become Agile Manufacturing, the business will need to invest in highly skilled and trained workers who are competent to be Agile.

- Ongoing need to keep machinery and workers up to date with new technologies and maintain company competitiveness due to short product cycle life.

- Maintenance to keep machinery in good working order increases the cost due to the higher cost of parts.

- Intensive planning and management of such a system is required as a shift from the ideology of mass production to Agile Manufacturing Methodology is ushered in.

Applications of Agile Manufacturing

The applications of Agile Manufacturing Process are

- Many companies have implemented what can be considered agile manufacturing.

- Motorola has developed an automated factory with the ability to physically manufacture stand-alone pagers on the same production line.

- At Panasonic, a combination of flexible manufacturing and just-in-time processing are used to make bikes by assembling a set of basic parts.

- One of the main facilitators of the agile manufacturing environment is the industrial robot.

- In addition, many lighting materials management applications often require a degree of judgment or decision making that is beyond the capabilities of most manufacturing equipment.

- This is especially true in electromechanical assemblies. For example, cutting a ribbon cable from a motherboard to a drive shaft on a custom computer assembly line is a difficult task performed by humans.

- However, it is also true that more manufacturers could benefit from adopting agile construction in many of their tasks that do not require such finesse.

Conclusion

Product designs for manufacturing and assembly play a critical role in making feeding and assembly easy. Agile part feeding can be addressed with flexible part feeders that leverage machine vision. Modular worktables and conveyor branches are key concepts to optimize the use of valuable robotic workspace, as well as to support rapid transition to new assembly tasks.

Agile Methodology Process of Agile Manufacturing does not contribute to any other manufacturing concept to incorporate elements and extension of then-documented best practices to support agile manufacturing, as long as they are collectively integrated to achieve agility.

Frequently Asked Questions

Q. Compare Agile Manufacturing Methodology with other Manufacturing Methods.

Ans. The long cycle time in the traditional manufacturing system, coupled with high inventory, leads to delays in product delivery. The problem here is the lack of strategy and not the involvement of employees, financial secrecy and inaccurate records. The advantages are long-term profitability, improved productivity, and shorter time to market, in contrast to the traditional manufacturing system in terms of world-class manufacturing.

An Agile Manufacturing System that focuses on the integration of all aspects of design and construction and construction under one roof. Different from the traditional construction strategy, agile construction focuses on customer promotion, competitiveness through collaboration and this can be achieved through the integration of people, information and technology under one roof.

This can also be achieved by a highly educated and skilled workforce. The increase in competition between competitors and the construction of the cooperation of all companies and therefore affects the exchange of knowledge and the exchange of technological innovations.

Q. Explain the needs of Agile Manufacturing System?

Ans. The key to agility, however, lies in many places. An agile company needs highly trained and knowledgeable people who are flexible, motivated and sensitive to change. An agile enterprise also requires new forms of organizational structures that foster non-hierarchical management styles and encourage and support people, collaboration and teamwork. Agile manufacturing companies also require advanced IT technologies to integrate information and share the knowledge base.

To achieve Agile Manufacturing, companies must bring together a wide range of knowledge in the design of a manufacturing system that engages suppliers and customers. It should also address all dimensions of the system, including organization, people, technology, management accounting practices, etc.

Most importantly, the interrelated nature of all of these areas should be recognized and an interdisciplinary building systems design methodology adopted as standard practice. This means looking at cross-business areas, going beyond the multidisciplinary approaches currently pursued.

Q. Explain the challenges of Agile Manufacturing Methodology?

Ans. Interdisciplinary design will form the base for Agile manufacturing systems design in the new knowledge-ferocious period. Interdisciplinary design, still, is further than applying knowledge from other disciplines, like psychology and organizational wisdom, to the design of nimble manufacturing systems. It also means looking for uncharted areas between these disciplines and the areas where they lap, to find a new perspective, new knowledge, new and original results.

This is one of the most important challenges that system directors, contrivers and integrators will face in the coming times. Interdisciplinary design leads us to new perspectives and new ways of thinking and working.

Still, in order to successfully borrow an interdisciplinary design methodology, we also have to

- Question current design strategies and develop new and improved approaches.

- Challenge established and nurtured beliefs and principles, and developed new ones to replace those that no longer held any validity.

- Consider how to address organization, people and technology, and other issues in the design of construction systems so that systems achieve better performance for the agile construction environment and the people who are part of the system. Challenge current design strategies and develop new and improved methods.

Utilize innovative technology in a way that makes human skills, knowledge and intelligence more effective and productive that allows industries to harness the creativity and talents of all people in an enterprise.