What is Cam Follower?

A Cam Follower also known as Track Follower, which is a special type of Needle or Roller Bearing designed to follow a Cam. Cam Followers come in a wide variety of different configurations like knife edge follower, roller follower, spherical faced, flat faced follower, etc. The most defining feature, however, is how they measure its mating portion; for example, Stud-Style cam follower uses a bolt; while the yoke-style has a hole in the middle.

Do you know…

The modern stile-type follower was invented and patented in 1937 by Thomas L. Robinson of the McGill Manufacturing Company. He replaced himself using a standard bearing and bolt. The new cam followers were easier to use because the bolt was already included and could handle more loads.

When two links are joined together either along a line or at a point, it is called a higher pair. An elevated pairing mechanism known as a Cam and Follower, which consists of two closely coupled systems. To work smoothly, it is essential that the follower moves smoothly without requiring a lot of input power; it means the follower will not become trapped during its movement.

Table of Contents

What is a Mechanical Cam?

A cam is a reciprocating, oscillating, or rotating body that transmits reciprocating or oscillating motion to the follower, a second body with which it is in contact. The form of the cam is determined by its own motion, and the shape of the follower’s contact face.

More About Cam Follower…

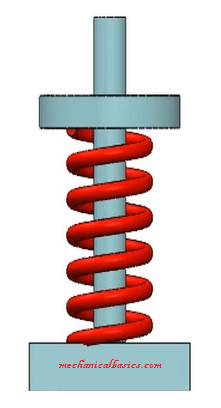

A follower is a translating or oscillating mechanical component that follows the movement of the mechanical cam. It might be spring-loaded or contact the cam’s surface profile. It might have a constant velocity or a constant acceleration speed. Complex output motion may be generated via trailing motion. Followers are used to transform circular motion into linear motion (replicating), which require employment of follower in addition. The followers rise and fall as the cam spins, a phenomenon known as reciprocating motion.

Types of Followers

The Cam Followers are divided according to different factors, they are

- According To The Shape Of Follower

- According To The Motion Of The Follower

- According To The Path Of Movement Of Followers

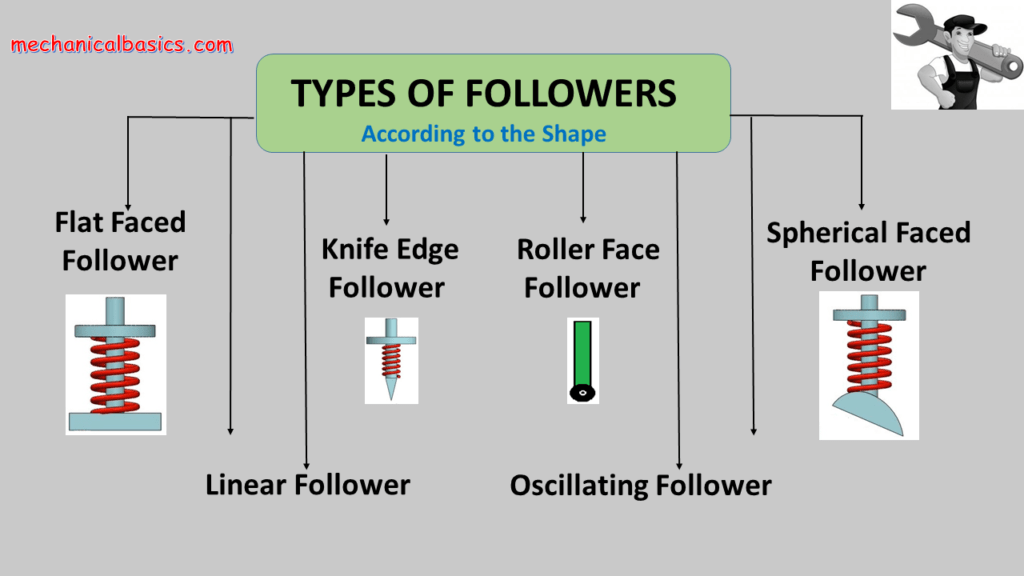

Types of Followers (According To The Shape Of The Follower)

The types of followers according to the shape

- Knife Edge Follower

- Roller Follower

- Spherical Faced Followers

- Mushroom Or Flat Face Followers

- Linear Follower

- Oscillating Follower

Knife Edge Follower

A knife-edge follower, as the name implies, has a sharp knife-edge that comes into contact with the cam. The motion is created by the cam and the sharp knife edge. A significant side thrust exists between the guide and the followers in this follower. The construction is simple, but it is only theoretical because a knife edge follower is never used because of the very high wear and tear at the point of contact.

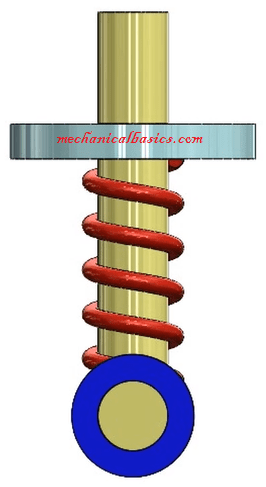

Roller Follower

In roller follower, the area of contact of cam and follower is in the structure of rollers and the rolling motion is taking place between the contacting surfaces so possibilities of wear seem to be much less, we can say it is negligible. This follower is frequently used because of its minimal wear, and the cylindrical roller is free to move about the pin joint.

These followers have a pure rolling action at low speeds, but it also skids at high speeds. The roller follower, like the knife-edge follower, has a side thrust between the guide and the follower. These sorts of followers are employed in applications where space is not an issue, such as aviation engines and some oil and gas engines.

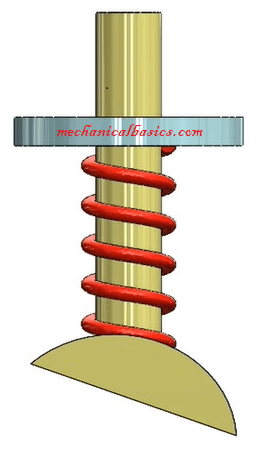

Spherical Faced Followers

The contacting surface of these followers is spherical in form. These are utilized to reduce the tension that is commonly observed in flat face followers. High surface tensions are created at high speeds in the case of flat face followers. To reduce all of these stresses, the flat face of the follower is modified into a spherical shape; as a result of this changed shape, relatively few stresses are created in the follower, and it may be employed in high-speed engines.

Mushroom and Flat Face Followers

The follower surface which is in contact with the cam in the form of a flat surface is called a flat face follower and if the follower surface which is in contact with the cam in the form of a mushroom (spherical in shape) is called a mushroom follower. There is extremely less side thrust in this case compared to the roller and knife-edge follower, which makes it stable even at high speeds and prevents the cam from jamming.

The fundamental disadvantage of these followers is that large surface stresses are created owing to misalignment and deflection. High wear is caused by these generated strains. Where space is restricted, this follower is employed in the valve opening mechanism of automotive engines; both in Four Stroke Engine and Two Stroke Engine.

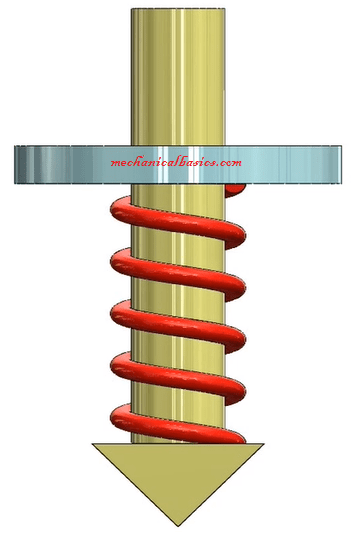

Linear Follower

If the follower moves in a straight line, it is referred to as a translating follower. The translating follower, whose axis of that prismatic pair crosses through the cam centre, is referred to as radially translating. When the follower axis passes through the centre of the camshaft, it is referred to as a radial translating follower. If it has a slight offset, which implies that the axis of the follower’s translation does not cross through the cam center, it is referred to as an offset translating follower.

Oscillating Follower

The cam spins as previously, but this time the follower oscillates owing to the geometry of the cam, and the follower is hinged at this point. As a result, this is known as an oscillating follower.

Types of Followers (According To The Motion Of The Follower)

According to the motion of the follower, there are two categories of followers

- Reciprocating or Translating Followers

- Oscillating or Rotating Followers

Reciprocating or Translating Followers

The motion of the follower in this kind is reciprocating or translating in the guides, whilst the cam spins evenly.

Oscillating or Rotating Followers

In this arrangement, when the cam rotates, the follower oscillates. The follower is pivoted at a fixed point where oscillating or rotational motion occurs in the follower.

Types of Followers (According To The Path Of Movement Of Followers)

- Radial Follower

- Off-Set Followers

Radial Follower

A radial follower is one of the types of cam followers in which the line of action of the follower’s motion goes across the centre of rotation of the cam.

Off-Set Followers

Off-set followers are those who have the line of action of motion of the follower offset/away from the centre of rotation of the cam.

Working Mechanism of Followers

Follower serves as a General Force in the X direction, and serves as a Common Force in the Y direction and two normal forces that balance the load moment.

The moment due to the force is taken as Fn. The frictional force that would try to oppose this vertical movement would be µ times the normal force. N as normal force, will be taken as μN.

During upward motion, the follower not only has to overcome these two frictional forces but also get rid of the spring force.

A follower is a part of the machine that spins the Cam in an oscillatory or circular motion. The Cam’s push and pull are inhibited by the Follower. The motion is transferred to the relevant machine portion via a follower. So a large Fn is needed to overcome the frictional force, and the vertical component of Fn will overcome these two frictional forces and the spring force, while during a downward motion, the spring force helps to bring the followers down; Therefore, the contact force will be less.

Working Video of Types of Followers

Advantages of Cam Followers

The advantages of Types of Cam Followers are

- Cam and follower bearings are such that they are always evenly distributed, regardless of the configuration of the unit.

- A wide range of linear motions are available from cams and followers.

- The cam follower can absorb more shock than usual and reduce distortion.

- They are extremely versatile.

Disadvantages of Cam Followers

The disadvantages of Types of Cam Followers are

- Backlash between cam follower and cam.

- It should be stopped to prevent much damage when the machine crashes.

- More expensive to manufacture and require more precision to machine.

- Negative radius of curvature is not possible.

Applications of Cam Follower

The applications of Types of Cam Followers are

- These are used in wall clocks.

- They are used in the feed mechanism for automatic lathe machines.

- Screw pieces of machinery.

- Gear cutting machinery.

- In printing machinery, this mechanism helps to screen prints. The push helps to pick up the positions where the printing will take place, and the pull helps to print on it.

- In hydraulic systems, these are the main mechanisms.

- Even in cloth-type machinery, the cam and follower mechanism helps the fabric to be sewn with a single push and pull. In that case, the system is dependent on the pressure of the fluid.

- Automated types of machinery, cams and followers use various parts that are automatically in motion.

Conclusion

Generally, a cam follower pair operates under critical conditions due to variations in load, speed, and radius of curvature that produces a large variation in film thickness. Contact can range from perfect to mixed to limit lubrication conditions and cause friction and wear problems. It is not easy to study in depth what happens in the contact of the cam follower, so the pilot study is necessary but very complicated.