What Is Welding Joint?

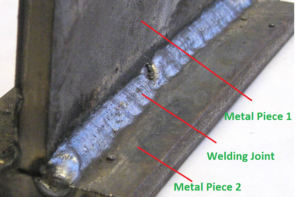

The Welding Joint is a type of joint, where two metal pieces are joined with the help of filler metal; the joint may be permanent or temporary. Whereas, the welding is the process of attaching or combining two pieces permanently (Read about oxy-acetylene welding). The Welding Joint Design is depend upon the type of application and requirement of the welder. There are different types of welding joints and each of them consists its own importance.

The surface where the metal will be melted while welding is called Faying Surface. The different types of Welding Joints offer a great strength, and rigidity to the material so, it cannot fail while working. Moreover, the welding joint has low-weight therefore, it cannot reflect in material application.

Also Read

- Arc Welding – Types of Arc Welding, Their Working, Advantages, Disadvantages, And Applications

- Resistance Welding – Its Types, Parts, Advantages, Disadvantages, And Applications

What can you learn from this post?

- Types of Welding Joint

- Butt Joint Welding

- Lap Joint Welding

- Tee Joint Welding

- Edge Joint Welding

- Outside Corner Joint or Corner Joint Welding

- Advantages of Welding Joint

- Conclusion

- Frequently Asked Questions

Types of Welding Joint:

There are different types of welding joint according to the application and requirement. The types of welding joint also may be used to acquire good strength too. The two metals are well-shaped using a grinding machine before welding them. The process of shaping the welding edges or spots on each workpiece is called Edge Preparation. The various types of welding joint are as follows:

Butt Joint Welding:

Butt Joint is one of the types of welding joint that can be found frequently. The two metals placed on the same plane parallel to each other and welded in the gap between them. The filler metal will be gathered and make a pool in the gap of the two metals, as the molten metal cools down the weld will acquire high strength.

We can observe the V-shape in between the two metals in Butt Joint Welding, that’s what we call edge preparation. Such preparation is used to achieve the deep welding so the filler metal will go into the gap and gives a greater grip.

Lap Joint Welding:

Lap Joint is one of the types of welding joint whereas; the welding is performed on two sides of the metal pieces. In Lap Joint Welding, the two metal pieces are placed one over another and the welding is performed at the edges of the metal pieces.

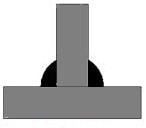

Tee Joint Welding:

The Tee joint is a type of joint that the metal pieces placed in such a way that we can observe the inverted T-shape or T-shape. One of the two metal pieces is placed vertically over the horizontal metal pieces and welding at the intersecting points. If the thickness of the two metals is more, then it needs more strength; to achieve more strength the edges are grooved so, the weld will go into the groove to give more grip and strength.

Edge Joint Welding:

The process of performing the welding at the edges of two metal pieces is called Edge Joint. The two metal pieces are shaped well so, the surfaces will be fine and free from rough surfaces. After shaping the surface, both metals kept in contact and welded at the edges in the Edge Joint Welding.

Outside Corner Joint or Corner Joint Welding:

The process of welding the metals at its corner is called Corner Joint or Outside Corner Joint. If we observe carefully, the Tee joint and Corner Joint look similar but the difference between the both (Tee Joint and Corner Joint) is the placement of the metals and welding locations.

The two metals are positioned in such a way that the angle between the metals is 90 degrees. The metal edges are placed somewhat outside so that the corner can be welded.

Also Read:

- Types of Arc Welding – Their Working, Advantages, and Applications

- Spot Welding – Its Parts, Working, Advantages, and Applications

Advantages of Welding Joint:

The advantages of the welding joint are as follows:

- The different types of joints are used according to the situation. This type of joint will help to increase the strength (read what is strength) of the weld.

- The various types of welding joint will prevent the failure of material due to the incoming forces.

- The life of the joints and parts will be increased with various types of welding joint.

Conclusion:

Welding is the process of joining the metals permanently so, the different types of welding joint are used to reduce the incoming forces like tensile, compressive, etc. The strength of the joints in metal parts will be increased and reduces the failure chances. In the whole 5 welding joints, the butt joint and lap joints can be used frequently.

Frequently Asked Questions:

The welding joint is the joint of the two pieces joined with the help of welding. There are 5 types of welding joint mainly. They are

-

Butt Joint Welding

-

Corner Joint Welding

-

Tee Joint Welding

-

Edge Joint Welding

-

Corner Joint Welding

The Butt Joint Welding is one of the types of welding joint where the two pieces are aligned side by side and welded at their ends.

The Tee Joint Welding is one of the types of welding joint where the two welding pieces are aligned perpendicular to each other exactly at the middle (one in horizontally and another in vertical position one over the other) and welding at the intersecting areas.

The Lap Joint Welding is one of the types of welding joint where the two welding pieces aligned one over the other (both are in horizontal position or vertical position) but a small portion of their corners should be in contact with other and the welding is performed at the intersecting areas on the two sides of the pieces.

The Edge Joint Welding is one of the types of welding joint where the two welding pieces will aligned one over the other (both are in vertical position or horizontal position) totally and welded at their intersecting areas (definitely at the sides).

The Edge Joint Welding is one of the types of welding joint where one of the welding pieces placed vertically on one of the sides of the another welding piece. Then the welding is performed at the intersecting areas.