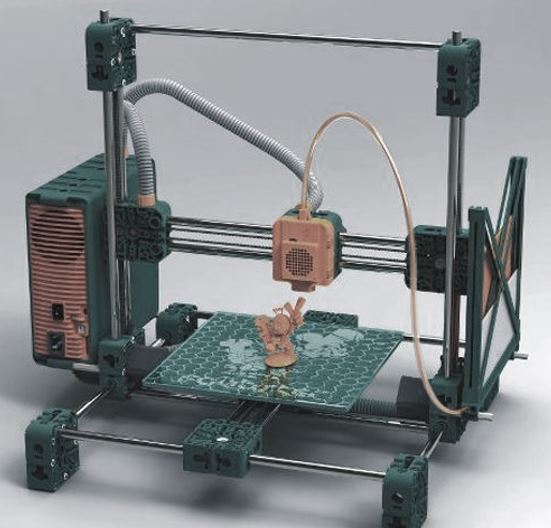

What is 3D Printing and 3D Printing Machine?

3D Printing, also called as Additive Manufacturing or Additive Manufacturing Process. The machine that manufacture or convert a raw material into required three dimensional object is called as 3D Printing Machine, which is also called as Additive Manufacturing Machine. This type of process uses Fused Deposition Modeling (FDM), and continuous Thermoplastic Material Filament to produce precise customized components. Moreover, a 3D Machine uses a layering process of Computer-Aided Design (CAD) to build three-dimensional solid items from a digital file, which is called as Input. This also involves stacking materials such as plastics, composites, or bio-materials to make items that vary in shape, size, stiffness, and colour.

3D printers are non-traditional manufacturing process, which do not involve any traditional manufacturing processes like Lathe Cutting, Milling, Shaping, etc. Virtually any geometry, even that cannot be created by using other traditional procedures, can be created by 3D Machine. 3D printing is just an opposite process to the Subtractive Manufacturing, which includes milling machine to cut or hollow out a piece of metal or plastic.

Also Watch Our YouTube Videos:

- Gear Hobbing Machine – Dissembly, Parts, Assembly, and Working

- Whitworth Quick Return Mechanism – Dissembly, Parts, Assembly, and Working

The production of a 3D items can be done with the use of additive techniques, which is the reason why we call 3D Printing Process as Additive Manufacturing Process. Firstly, a solid object is built with an additive technique by laying down successive layers of material until the product is complete. Further, each of these levels or layers represents a finely cut cross-section of the item.

Note: You Will Read Types of 3D Machines in the Upcoming Blogs

Material Used in 3D Printing Machine

3D printers are configured to operate with a broad variety of materials like Additives. Custom-built systems can even combine various materials in a single structure to create more complicated goods with numerous colors or electrically conductive parts. Even when 3D printing has had a transformational influence on the industrial business, there is almost certainly be a demand for high-grade printing materials with exceptional qualities or innovative features.

Plastics

Plastics are the most often used material in 3D Machining (or Additive Manufacturing Process). In the Fused Deposition Modelling, the printing nozzle rotates and the plastic is extruded as a fine thread, forming the item one layer at a time. Plastics are great for 3D print due to their broad variety and inexpensive cost, especially in Rapid Prototyping applications.

Ceramics

Ceramics is also used to produce Three Dimensional Objects. These are normally treated differently; layer upon layer of ceramic powder is put in a block, while the structure is generated momentarily using a binder or a laser sinter. After removing the surplus powder, the solid piece is burned and glazed in a kiln.

Metals

Apart from Plastic, and Ceramics; Metals are also used to produce Three Dimensional Objects in the same manner that plastics are produced. Metal powder is sintered or a binder is added to form the structure. The object is held in place by the remaining free powder until the metal is fused at high temperatures and the remaining stuff is eliminated.

Also Read:

- Gear Hobbing Machine – Its Parts, Types, Working, Advantages, Disadvantages, Applications – FAQ’s

- Electrical Discharge Machine – Its Parts, Working, Advantages, Disadvantages, Applications – FAQ’s

Advantages of 3D Printing Machine

The Advantages of 3D Printing or 3D Machine are as follows

Flexibility

We can also create 3D parts or components. With an online 3D Machining service like Sculpteo; you can generate what you need or on-demand.

Rapid iteration

If you need to accelerate product development, additive machining is a wonderful option. You will benefit from improved and more efficient iteration management. Time is money, and money is valuable when it comes to operating a business and generating initiatives. Saving time and shortening your whole product development cycle is critical to your business.

Innovation

One of the most significant advantages of 3D printing is the design flexibility it provides. You can make all of your thoughts into physical objects by recreating them. Even the most intricate shapes are capable of being printed. You will be liberated from the constraints of traditional production by using 3D Machine. Creating a design using layer-by-layer method, is distinc

Mass Customization

Mass Customization has the potential to benefit a wide range of sectors from medicine to consumer products, manufacturing and automobiles. In the medical field, additive manufacturing enables the manufacture of made-to-measure prostheses or instruments. However, it also be used to make customized 3D printed glasses.

Shorter Assembly Lines

3D printing enables objects to be produced in a single stage, which results reduction of assembly stages. Manufacturing units will be smaller as a result, and they will function more efficiently.

Products with On-Demand Printing

The practice of “Just in Time” production will benefit greatly by 3D Machines. Manufacturers can make things as they are required due to short producing timeframes and adaptability of 3D printing technology.

Creative Product Design

The possibilities of 3D printing enable the utilization of shapes and structures that could not be done by any other way, especially not in big quantities. Artists and sculptors are already using the technology, and ornamental 3D-printed artifacts are commercially accessible.

Disadvantages of 3D Printing Machine

The Disadvantages of 3D Printing or 3D Machine are

Limited Materials

While 3D Machines can make products from a variety of polymers and metals, the accessible raw materials are not exhaustive. This is because not all metals or polymers can be thermally regulated sufficiently to allow 3D Print. Furthermore, many of these printing materials are not recyclable, and just a handful are food safe.

Post Processing

Most 3D printed items require some type of cleaning up the removal materials, from the build and smooth the surface to obtain the desired quality. Chemical soak and rinse, heat drying, Water Jetting, Assembling, Sanding and other procedures are used for post-processing which might impede the manufacturing process.

Design Inaccuracies

This potential issue with 3D Machine is directly tied to the type of machine or method utilized; certain printers have lesser tolerances, which means that finished items may deviate from the original design. This can be corrected in post-production, but keep in mind that it will increase the time and expense of production. The final finish of the models created using 3D printing is frequently inferior to that of models made using higher-end RP machines.

Applications of 3D Printing Machine

Modern 3D printing was created roughly 25 years ago, but it has only just begun to gain traction. Even though most of the technology is still in its early stages, the applications for 3D printing is very astounding.

Medicine

Due to diseases such as aging, wrinkling, and collapsing bodies, humans see immense hope in a technology that can manufacture new body parts and tissue. So, physicians were among the first to experiment with 3D printing. Already, we have seen 3D printed ears (from the Indian business Novabeans), limbs and legs (from Limbitless Solutions, Biomechanical Robotics Group, and Bespoke), and muscles (from Limbitless Solutions, Biomechanical Robotics Group, and Bespoke from Cornell University). 3D printers have also been used to create artificial tissue (Organovo), cells (Samsara Sciences), and skin (in collaboration with cosmetics giant L’Oreal).

The Wake Forest Institute for Regenerative Medicine in North Carolina runs a project called Body on a Chip, which prints small human hearts, lungs, and blood arteries install them on a microchip and test them with a type of artificial blood.

Defense and Aerospace

Designing and testing airplanes is a hard and costly business. A Boeing Dreamliner contains over 2.3 million components! Although computer models may be used to examine many elements of plane behavior, realistic prototypes are still required for tasks like wind tunnel testing. And 3D printing is a quick and easy technique to accomplish this. While commercial jets are mass-produced, military planes are more likely to be highly customized—and 3D Machine allows for the rapid and cost-effective design, testing, and manufacturing of low-volume or one-off parts.

Even in space stations, It is simple to envisage astronauts utilizing 3D printers to create whatever items (including spare parts) they want, whenever they need them. However, Earth-born space missions may benefit from 3D printing’s speed, simplicity, and low cost. The new NASA Rover, which is capable of sustaining humans, is made entirely of 3D-printed pieces manufactured with the assistance of Stratasys.

Visualization

3D printing is commonly utilized for prototyping and testing industrial and consumer goods. Because many daily items are made of plastic. A 3D Print model can seem extremely close to the completed product, making it ideal for focus-group testing or market research.

Conclusion

It is widely assumed that 3D printing will be a transformative force in manufacturing, whether in a positive or bad way. Despite worries about counterfeiting; numerous firms are already employing the technology to make sophisticated components in a repeatable manner, such as in automotive and aerospace production. So, we can say that the 3D Machines will be the future that can manufacture or develop any type of 3D Objects using the help of Computer Aided Designing (CAD).

Frequently Asked Questions

Can CATIA V5 software be used in a 3D printing machine platform to create objects?

Catia V5 can be used to create your model. You may save it as the native Catpart format or as STP and STL files, depending on what the 3D printer application supports. After that, convert to G codes to print.

What is the use of metal 3D printing?

3D printing is most commonly linked with prototype and sophisticated part designs. Metal 3D printing is used to add detailed patterns to items that would otherwise be impossible to cast or forge. Despite the actual cost, significant and the materials that may be utilized are restricted.

The turbocharger housing used in the Koenigsegg 1:1 is one such example. The shell contains various channels for the engine at high and low speeds, which helps to reduce turbo lag. Due to the complexity of the design, it was manufactured via 3D printing.

How could machine learning be used in 3D printing?

For FFD printers the very first thing to check is the slicing software. It’s 95 percent math, but ML might make a difference in the final 5% by optimizing speeds and infill somewhat better. Additional improvements that can be made would be the addition of a real-time camera and/or a real-time filament diameter sensor. A camera and machine learning may be able to help the printer adjust for extrusion difficulties and, at the very least, recognize when to give up and cease printing.

What is the difference between 3D printing and CNC machines?

The difference between the basic method is,

CNC works on block materials and external surface machining to create the frame component that matches the 3D model. The principle of subtractive manufacturing is used by CNC machines.

Powder (or resin) materials are used in 3D printing. It produces layer by layer with a thickness of around 0.050.25mm. The additive manufacturing principle is at the heart of 3D printing.

What is the future of 3D printing?

3D printing has the potential to democratize the fabrication of commodities ranging from food to medical supplies. 3D printing devices may one day find their way into homes, companies, disaster zones, and possibly outer space.