What is Thermosetting Polymer And Thermosetting Plastic?

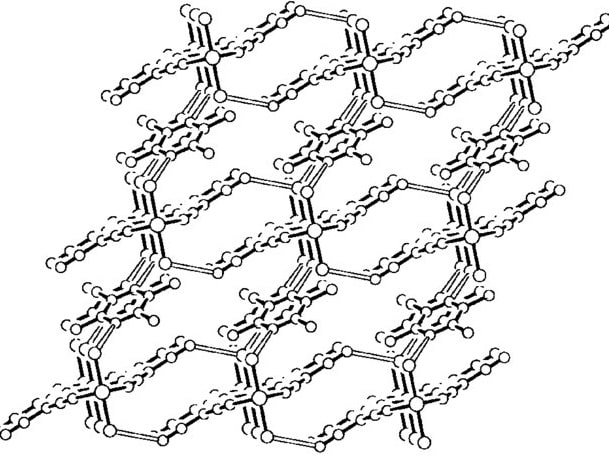

Thermosetting Polymer or Thermosetting Plastic or Thermoset is a family of plastics that is characterized as that they start from a liquid solution by irreversibly hardening using heating step or treating with specific temperature. They exhibit an opposite behavior in comparison to thermoplastic polymers, which, with few exceptions, show a reversible solid-to-liquid transition when heated to a comfortable temperature. Even though the irreversible liquid-to-solid transition can also be carried out by UV or Electron Beam Irradiation, the resulting products are also known as thermosetting polymers. The process of converting the initial liquid solution into a solid is known as Curing of the material, which results in cross-linked 3d structure or network chains.

Usually the initial liquid solution is composed of several ingredients but the most important is a mixture of comonomers that can react with external action such as heating, UV-radiation, etc.

Table of Contents

Processing of Thermosetting Polymers

Thermosetting polymers are heated and treated in liquid form. Depending on the desired output; curing agents, inhibitors, hardeners, or plasticizers, etc., are added to the resin and reinforcement or fillers during the curing process.

Thermosetting polymers are made from a variety of materials that play important functions and serve important applications in the plastics manufacturing industry. The Reaction Injection Moulding (simply RIM) and Resin Transfer Molding (simply RTM) are the two thermoset molding compound methods (simply RTM).

Thermosetting Process:

The processing of thermoset polymers typically involves three steps.

- The first stage is known as the resol, during this stage the resin is an insoluble and fusible state.

- In the second step, thermosets are only partially soluble, and they exhibit characteristics of thermoplastics where the transformation is reversible. This is a temporary condition as the molten form of the thermoset lasts only for a short time, as the increase in temperature promotes cross-linking.

- The final stage is the cross-linking reaction and the formation of the final structure of the thermoset. It mainly consists of a molding step which is carried out at controlled temperature with some pressure.

After these steps the final product will have a cross-linked 3d structure or cross-liking three-dimensional internal network structure consisting of highly cross-linked polymer chains and the product can no longer be thermally deformed. Thermoset plastics can also be processed through a one-step method called Reaction Injection Moulding (RIM). This process is similar to the method described above but the only difference here is that the polymers come together during the curing process to form a permanent chemical bond. The process basically uses polymerization in a mold instead of cooling to facilitate the formation of a solid polymer.

Methods of Thermosetting Molding

Common methods of thermosetting molding include:

- Extrusion molding is used to make insulation for electrical wires, fabric wires, and pipes.

- Compression molding is used to shape BMC and SMC thermosetting plastics.

- Spin casting, which is a process primarily used to produce figurines, fishing lures and jigs, emblems, and even replacement parts.

Properties of Thermosetting Polymers

Thermosets are more chemical and heat resistant, with a tougher structure that does not deform easily. Thermosetting polymers have a cross-linked three-dimensional structure and the chemical and physical properties of the polymers depend on the components behind the polymer’s manufacture. Following are some of the basic properties of thermosetting polymers:

- Thermoset plastics are heat resistant. However, when high-intensity heat is applied, they dissipate before they reach the melting point.

- Thermosetting polymers are brittle in nature due to the loss of elasticity when heated.

- Once cured or shaped, these polymers cannot be reformed by the application of heat.

- The thermosetting density is dependent on the constituent components used to make the polymer.

- Thermosets generally are resistant to chemical attack.

Types Of Thermosetting Polymers And Their Applications

The different types of thermosetting polymers are

- Epoxy Resin

- Melamine formaldehyde

- Polyester resin

- Urea Formaldehyde

- Reaction Injection Moulding (RIM)

- Resin Transfer Moulding (RTM)

- RIM Thermosetting Plastics

Epoxy resin

- Epoxy Resins (polyepoxides), is a type of Thermosetting Polymer, is a certain class of organic compounds that contain epoxide groups, which are composed of carbon chains linked by covalent bonds such as nitrogen, oxygen, and hydrogen. This allows elements that have 2 electrons to bond with each other. As a result, polymers become elastic and rigid. This makes them ideal for various applications.

- In simple words, a polyp oxide is a thermoset that results from the reaction of 2 or more compounds. This reaction radiates heat and changes the material from liquid to granular/solid. It should be noted the the chemical reaction can take several hours.

- The advantages of two component epoxy outweigh the disadvantages. Two component epoxy resins cure easily at room temperature. They do not require any kind of heat. An epoxy piece requires heat. Two component epoxy provides excellent chemical resistance.

Melamine Formaldehyde

Melamine formaldehyde is obtained from the polymerization of Formaldehyde (chemical formula CH2O) with Melamine (chemical formula C3H6N6). Polymerization is a chemical process in which two or more identical small molecules, called monomers, join together to form a polymer cross-linked 3d structure chain. A polymer is a macromolecule, or larger molecule, consisting of linked monomers. Polymers are commonly called plastics.

It hardens when heated during its preparation and once set it cannot be reshaped or reconfigured to form a different shape and retains its strength and shape unlike other types of thermoplastics and softens when heated and hardens when cooled (such as acetate, acrylic, and nylon). Melamine formaldehyde is

- White

- Tasteless

- Odorless and Exhibits Great Chemical and

- Heat Resistance and Cannot Be Melted.

Polyester Resin

Polyester Resin is another type of Thermosetting Polymer, is formed by the reaction between organic acids and polyhydric alcohols. It is Hard, stiff and brittle when un-laminated, we can use it for various domestic and industrial applications. There are several types of polyester resins and their properties depend on the acid and alcohol used in their manufacture. A resin of polyester obtained by polymerization of simple molecules of certain compounds, and also secreted by coniferous trees.

Urea formaldehyde

Urea-formaldehyde commonly known as urea-methanol, which is manufactured with urea and formaldehyde. It is a non-transparent thermosetting resin. It has high tensile strength, high flexural modulus, high heat-distortion temperature, low water absorption, mold shrinkage, high surface hardness, elongation at break, volume resistance.

Reaction Injection Moulding (RIM)

- Reaction injection moulding (RIM) is similar to thermoplastic injection molding. It is a low pressure, low temperature process and used to mold many types of plastic parts in like medical, industrial and automotive industries. In this process, the highly reactive plastic fluid is mixed under high pressure and then injected into a mold to react, polymerize, and transform into a foamed plastic.

- The process involves high-speed mixing of two or more reactive chemicals as they are injected into a mold, the less viscous mixture fills the mold at relatively low temperatures and pressures, and the reactions are synchronized with the process. So that there is no jail while filling. The high pressure dosing unit is a key element of the process. It must deliver highly reactive starting materials to the mixing head with the precise timing of two liquid streams and, within a few seconds, inject them into the mold at high pressure using an impact mixer.

- The other key element is the mixing head, which must send each flow to the mixing chamber at high speed, receiving it at the right moment, in case turbulence develops in the mixing chamber so that the two currents mix completely. and quickly, and the camera should Clear it up There is no buildup. The mixture is allowed to remain in the mold for as long as it takes to progress to the point where the mechanical properties of the part can collapse.

RIM Thermosetting Plastics:

- PDCPD (polydicyclopentadiene)

- Polyurethanes

- Polyureas

- Structural Foams

Resin Transfer Moulding (RTM)

Resin Transfer Moulding (simply RTM) is low pressure molding process, in which a composite resin and catalyst are injected into a fiber packed closed mold and once the resin cures the mold can be opened and the finished component removed. RTM was introduced in 1976 by Osborne Industries. The resin transfer molding process has been in use since then and a wide range of resin systems were used in the following

- Vinylester

- Epoxy

- Phenolic And

- Methyl Methacylates

These things are combined with pigments and the fillers including aluminum trihydrate and calcium carbonate. The fiber pack may be either glass, carbon, aramid, or a combination of these. There is a large variety of weights and styles commonly available.

Resin Transfer Moulding is the best methods for mass production of mixed parts. It is primarily used to mold components with large surface areas, complex shapes, and smooth finishes. Automotives, industrial equipment and agricultural industries have used resin transfer molding processes for decades for these reasons.

RTM Thermosetting Plastics (Fiberglass-Reinforced):

- Polyester

- Vinyl Ester

- Polyimides

Advantages of Thermosetting Polymers

There are several advantages of thermosetting polymers and polymers. They keep their strength and form even when heated, unlike thermoplastics. As a result, thermosetting polymers are ideally adapted to the manufacture of permanent components and massive, solid forms. Furthermore, these components have outstanding strength characteristics (despite being brittle) and will not lose substantial strength when subjected to higher working temperatures. Thermoset polymers have grown in favour among manufacturers, who have begun to utilize them as a lower-cost alternative to metal components.

The advantages of thermosetting polymers have over metal counterparts include:

- Tolerances that can be molded-in.

- Color and surface finish options.

- Performance and a high strength-to-weight ratio.

- Excellent dielectric strength.

- Microwave transparency and low thermal conductivity.

- Water resistance and corrosion resistance.

- Reduced tooling and setup costs.

- Decreased production costs compared to metal fabrication.

Disadvantages of Thermosetting Polymers

The disadvantages of Thermosetting Polymers are

- The usage of thermosets has several drawbacks since the material characteristics are not as established as these of thermoplastic polymers.

- The low starting viscosity of heavy materials flash and necessitates subsequent procedures. Furthermore, it has poor tensile strength and ductility tend to result in components that necessitate thick-walled designs.

- The chemicals employed in thermosets are reactive systems, which can have an effect on the usable shelf life.

- Batch procedures may have more variety and less consistency from lot to lot.

- Excessive tool wear may come from high quantities of certain filler in the materials.

- The degree of cross-linking established during the molding stage determines the product quality.

Applications of Thermosetting Polymers

The Applications of Thermosetting Polymers types are

- Epoxy resin is a highly versatile product used in a wide variety of industries, covering a wide variety of materials including metals, glass, wood and fabrics. The incredible heat resistance property makes it a great adhesive product for creating useful items such as coasters, tumblers, bookmarks, shakers and more. It has excellent gap filling property too. The epoxy is resistant to cold, radiation, and steam. The epoxy maintains its superior performance when exposed to adverse environmental conditions. Its Bio-compatibility, Eco-friendly, Flame Resistant, Food Safe.

- Melamine Formaldehyde are used as particleboard and plywood adhesives in automotive coatings, epoxy coatings and polyester appliance coatings.

- The main applications of Polyester resins are in the construction industry (non-reinforced or glass fiber reinforced products), the automotive industry and in industrial wood and furniture finishing.

- Some of the applications of Urea Formaldehyde include laminates, textiles, paper, wrinkle resistant Fabric, cotton blend, foam artificial snow and coating for electrical appliances such as desk lamps.

Generally, the types of thermosetting polymers are

- Types of thermosetting polymers are high-performance providers and their applications includes the automotive, appliance, electrical, lighting, and energy markets, due to their exceptional chemical and thermal stability, as well as their superior strength, hardness, and moldability.

When complicated and geometric shapes cannot be obtained through metal fabrication or the use of thermoplastics but may be made in a mold, thermosets give an alternate approach. Thermoset polymers remain stable in all conditions and temperatures.

Conclusions

Thermosetting polymers are cost-effective, lightweight, and durable with excellent mechanical and physical properties. due to their unique chemical bond and long chain that makes them widely accepted now they have replaced most of the traditional engineering materials.