What Is Two Stroke Engine?

The Two Stroke Engine is an Internal Combustion Engine that is used to develop power. The Engine is used to convert the Chemical Energy (petrol or diesel) into Mechanical Energy. We already read about the Four Stroke Engine that consists of Four Strokes and Four Processes similarly, the Two Stroke Engine does consists of Two Strokes, and Four Processes. In this type of internal combustion engine, the four processes will be completed in One Revolution of the Crankshaft.

Parts Of Two Stroke Engine:

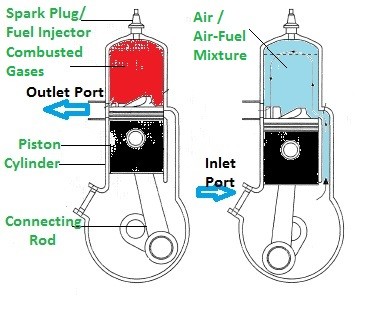

As like the four stroke engine, the two stroke engine do consists of similar parts but the construction and working are different. In the four stroke, the engine consists of Valves that help air and gases to enter and leave the cylinder but in the Two Stroke, we call them Ports. So, the parts of are:

- Inlet/Suction Port: It is used to suck the air from the atmosphere into the Engine or system.

- Outlet/Exhaust Port: It is used to send the air from the system to the atmosphere.

- Piston: It is the source that helps to perform the whole operations like sucking, compressing, and sending the gases outside.

- Connecting Rod: It connects the piston and crankshaft. It will convert to and fro motion of the piston to the rotary motion.

- Spark Plug/Fuel Injector: It will produce fire and results in the combustion of fuel.

- Crankshaft: The rotary motion of the engine can be achieved by the crankshaft.

Working Of Two Stroke Engine:

The Two Stroke Engine do consists of Four Process which results in two strokes of the engine. The four process are

- Suction Process

- Compression Process

- Combustion Process

- Exhaust or Expansion Process

Let us study about those four processes in detail.

1. Suction Process:

The Two Stroke Engine does consists of two ports; inlet and outlet. The inlet port is used to suck the air from the atmosphere. (If the engine uses the diesel as its source then the engine will suck the air as its source. If the engine uses petrol as its source then the engine will suck the air-fuel mixture as its source).

At the time of sucking the air or air-fuel mixture, the piston will be at Bottom Dead Centre (at the bottom-most position of the cylinder that piston can move), the air or air-fuel mixture will enter into the cylinder through the bottom side of the piston and moves to the top of the piston through the transfer port. So, this process is called Suction Process.

2. Compression Process:

As soon as the air enters into the top of the piston, the inlet port will be closed automatically and the piston will move to the Top Dead Center (a topmost position that the piston can move upside) by compressing the entered air. As the piston is compressing the air, it is called Compression Process.

At the time of compression, the inlet and exhaust ports are closed and no input and output will be take place.

In this process, the piston moves from the bottom dead center to the top dead center whereas; the movement is called Compression Stroke.

3. Combustion Process:

At the end of the compression process, the piston reaches the top dead center or top position; the combustion of gases is achieved.

Combustion process in Diesel Engine:

If the two stroke engine is used in a diesel engine; the cylinder will achieve a great temperature due to the compression process and the fuel injector will release the small tiny particles of diesel to perform the combustion in the cylinder.

Combustion Process in Petrol Engine:

If the two stroke engine is used in a petrol engine; at the end of the compression process, the spark igniter will release the tiny sparks to combust the air-fuel mixture.

The process of combustion of air-fuel or fuel in the cylinder is called Combustion Process.

4. Expansion Process:

Due to the combustion process, the piston will move downward direction and the exhaust or outlet port is automatically opened and these combusted gases will be sent outside. The process of sending the combusted gases out of the cylinder is called Exhaust Process or Expansion Process.

The movement of the piston from the top dead center to the bottom dead center is called the Expansion Stroke or Power Stroke.

In the whole four processes, the engine will generate the power only from the combustion process and after using the power for expansion of the piston, the extra power will be stored in the flywheel to perform the other three processes or remaining one stroke.

So, the four processes and two strokes will be resulting One Revolution of the crankshaft. This is the working of two stroke engine with four processes and two strokes in one revolution.

Also Read:

- Advantages of Four Stroke Engine Over Two Stroke Engine

- What is Four Stroke Engine, Working of Four Stroke Engine, And Its Advantages?

Advantages Of A Two Stroke Engine:

- Develops more Power compared to the Four Stroke Engine.

- It does result in Uniform Turning Moment.

- Its operations are simple and easier.

- Its Construction is simple.

Applications Of A Two Stroke Engine:

- The applications of Two Stroke Engine are less in Automobiles due to the advantages of four stroke engine.

- These are used in Compressors to develop high Power.

- They are used at the places where the economy of mileage is negotiable and high power is necessary.

Conclusion:

Two Stroke Engine can able to generate great power than the four stroke engine but the economy and consumption of fuel are not as notable as four stroke engine. The efficiency of the two stroke engine is less. The construction is simpler but it is not as popular and usable as four stroke engine. But it can be used in many places other than automobiles nowadays. It does have its significance and importance in its way of performance.